Speed Increasers Optimize Machine Parameters

IMTS 2022: Available for the most current Citizen models, the 1:4 speed increasers are said to optimize the machine’s parameters, making them both efficient and cost effective.

Share

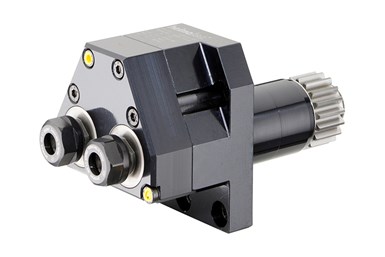

Heimatec Citizen Multiple Spindle Tool 2X ER11. Photo Credit: Platinum Tooling

Platinum Tooling Technologies — the exclusive importer of Heimatec live tools, angle heads and multi-spindle heads — has expanded its line of live and static tools for Swiss-Type CNC automatic lathes to the current Citizen tool program. In addition to the standard live and static tools, it will offer 1:4 speed increasers for the most current Citizen machine models. Designed to optimize the machine’s parameters, it is said these precision tools are efficient and cost effective.

Originally developed for the manufacture of precision parts in the watch industry, Swiss-type CNC Automatic Lathes are now widely used throughout the industry to produce automotive components, screws and pins for the medical industry, and precision parts for electrical engineering.

Platinum Tooling and Heimatec’s goal during the development of this line was to construct a series of tools that would offer the greatest possible processing quality and longest service life, while additionally enhancing the machine’s capabilities with the use of speed increasers. To achieve this, Heimatec says it incorporates the highest quality bearings, ground gear components, spindles and housings to produce superior tools with maximum rigidity.

Related Content

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.