Tooling

Applying A High Speed Machining Discipline Without The Speed

In this shop, high speed machining makes sense at 4,000 rpm. While the disciplines the shop put in place made a new 15,000-rpm profiler dramatically more productive, high speed machining would have remained valuable even if the new machine never came. Acoording to a co-owner of this shop, high speed machining has no need for speed.

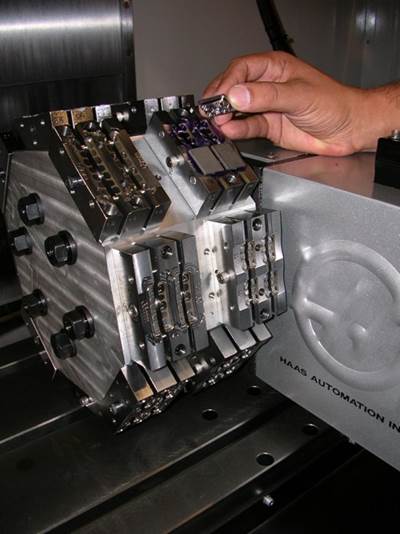

WatchChuck Helps Restore Thin-Walled, Hardened Parts To Roundness

Heat treating can distort parts, especially round, thin-walled workpieces. During finish-turning, such components can conform to the shape of the chuck, only to spring back to an out-of-round state after clamping. Hardinge has developed a chuck with multiple gripping fingers to avoid this problem.

Read MoreGet Better Before You Get Bigger

Rather than making a major new machine tool purchase just yet, this shop is finding additional capacity on the equipment it already has. What once was a vertical machining center will become a flexible automated production center for unattended machining.

Read MoreSmoothing Insert Surfaces Extends Tool Life

A post-coating finishing process smoothes any cracks in the outer coating of a cutting tool insert that develop during CVD and also removes droplets that PVD might leave behind. The resulting reduction in friction, heat and surface stresses is said to extend tool life and cutting performance.

Read More