Tooling

Learn From Your Mistakes

Admit it. There have been instances in which an operator’s mistake or a programming error turned one of your shop’s perfectly good cutters into a deformed creature.

Read MoreTurning Is Optional

The part requires only milling and drilling, but it is still run on a lathe. Except for the cutoff tool, all of the turret positions on this lathe hold rotating tools. In other words, turning is not essential for using a lathe effectively. This application illustrates the productive possibilities of a modern turn-mill machine.

Read MoreLending A Hand To The Machining Center

This coolant-operated gripper loads in the spindle like a toolholder, allowing the machining center to lift and move its own workpieces.

Read MoreMeasuring Taper For Toolholders And Spindle Applications

Companies concerned about strict quality requirements regularly check toolholder tapers for wear or inaccuracy because these conditions can jeopardize the results of a critical operation. However, a shop can check tapers quickly and reliably with air gages. These devices can be used effectively without special operator training. For measuring taper in a production environment, few other methods can match the speed and performance of air, as multiple-circuit air jets can be placed in very small taper gages.

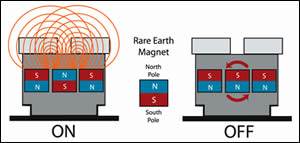

Read MoreAttracted To A Better Way

Modular, magnetic workholding blocks have changed the way this shop approaches the machining of both large and small workpieces. The blocks’ portability allows them to be used on a variety of different machines. Their flexibility often eliminates the need to create custom fixtures.

Read More