Tooling

Kyocera Turning Grade Provides Tough Cutting Edge

The Megacoat Tough coating combines a wear-resistant layer on the surface adhered to high-content CBN, which provides greater fracture resistance when encountering interruptions.

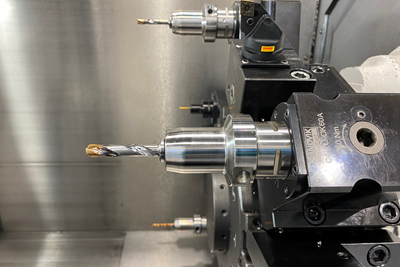

Read MoreKay Engineering's Gundrilling Machine Performs Range of Operations

Kay Engineering’s DeHoff 20144 is used to perform gundrilling, pull boring, roller burnishing and thread tapping.

Read MoreWalter Indexable Inserts Provide Improved Wear Resistance

WBH20C indexable inserts provide excellent layer bonding and long tool life due to the patent-pending method for pretreatment.

Read MoreStar Cutter Enhances PCD Tool Reconditioning Services

Star Cutter provides reconditioning for its own PCD products, as well as other manufacturer’s tools.

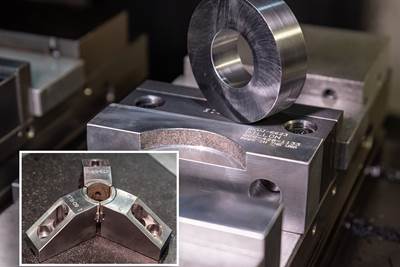

Read MoreDillon's Carbide Coating Increases Jaw Gripping Force

Carbinite is a wear-resistant, textured carbide coating that reportedly doubles the gripping force of jaws.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

WatchForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreSMW Autoblok's Workholding System Removes Obstacles

Eastec 2023: MillTec makes it is easier to carry out complex operations with five-sided access to the part.

Read MoreWalter Xtra-tec XT Milling Tools Feature Pocket Design

Eastec 2023: Walter’s Xtended Technology (XT) milling tools offer large cross-sections for maximum tool stability and a larger contact surface for a secure seat and reduced surface pressure.

Read MoreSimulation and Tooling Secure High-Value Work

Simulation software and careful attention to tooling parameters have enabled Major Tool to take on ambitious projects with its complex machinery.

Read More

.jpg;maxWidth=300;quality=90)