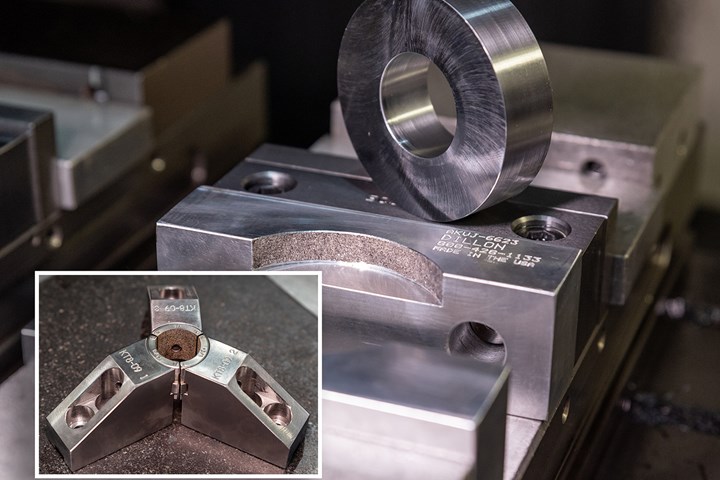

Dillon's Carbide Coating Increases Jaw Gripping Force

Carbinite is a wear-resistant, textured carbide coating that reportedly doubles the gripping force of jaws.

Share

Dillon Manufacturing has effectively doubled the gripping force of its jaws with the addition of carbinite, according to the company. Carbinite is a wear-resistant, textured carbide coating that is added to hard or soft jaws after they are milled. Using a process called electro spark deposition (ESD), carbinite reduces or eliminates slippage, improving the grip on workpieces to enhance mill performance and reduce cycle times. This wear-resistant carbide alloy is said to display exceptional bond strength without annealing or distortion.

In Dillon’s clamping tests, carbinite nearly doubled the gripping strength at equal clamping force. Customers reported increased grip and longer tool life. Carbinite is ideal for hard or soft jaws, especially vise jaws and step jaws used for clamping applications, as well as collet pads and jaws.

Carbinite is made in the U.S. in ISO 9001:2015 registered facilities.

Related Content

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

.jpg;maxWidth=300;quality=90)