Star Cutter Enhances PCD Tool Reconditioning Services

Star Cutter provides reconditioning for its own PCD products, as well as other manufacturer’s tools.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

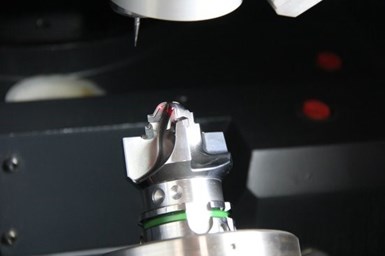

Star Cutter’s Tool Reconditioning Center includes laser equipment offering very fine cutting for reconditioning of highly complex PCD tools. Photo Credit: Star cutter Company

Star Cutter has added a Lasertec precision laser cutting machine to its Tool Reconditioning Center. This machine enhances the company’s ability to quickly restore polycrystalline diamond (PCD) tools to their original condition, helping lower the cost of ownership over the life of the tool for its customers.

The Lasertec can handle highly complex tools, offering very fine cutting and the ability to address a smaller inside radius and sharper cutting edge on the PCD than EDM technology. The laser machine also offers high repeatability and reproducibility with a positioning accuracy of ≤ 0.2032 μ. Additionally, there is less handling of the tool that has chip breakers, as the lasered chip breakers can be machined in the same step and position as when the cutting edge is made, eliminating the need for a second clamping operation.

Star Cutter provides reconditioning for its own PCD products — 3D-printed tools, circular mills, interpolating tools, facemills, combination tools, reamers and drills — as well as other manufacturer’s tools. The reconditioning center is equipped to repair these products to their original conditions.

Related Content

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.