Tooling

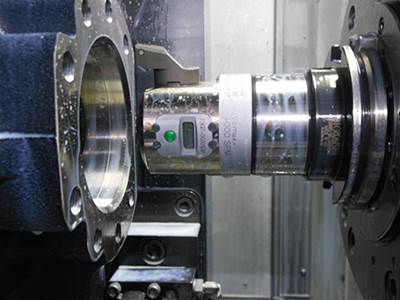

Digital Tooling Improves Accuracy, Reduces Scrap

By switching to digital boring heads, Impact CNC was able to reduce its scrap rate while increasing precision.

Read MoreUltrasonic-Assisted Machining with Standard Machines and Tools

A system to be marketed in 2015 will apply ultrasonic vibration from within the toolholder to reduce cutting force and improve the performance of the cut.

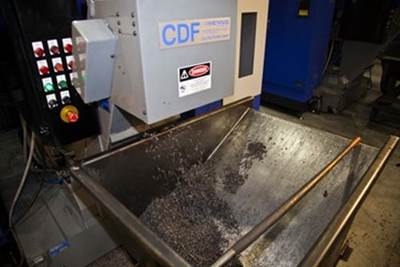

Read MoreCase Study: Chip Conveyors Run Production Efficiently

Hennig chip conveyors on Niigata machining centers maintain efficiencies and production on ductile iron castings used in heavy truck and military drive train projects at this Michigan shop.

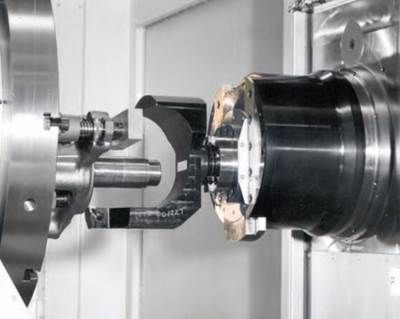

Read MoreHMC Delivers Turning, Drilling, Milling with Single Clamping

The Heckert DBF 630 HMC, available from Starrag, enables turning, drilling and milling of non-rotational, asymmetrical parts in a single clamping with one toolholder.

Read MoreExtreme Part-Off Demos at IMTS 2014

The strength of part-off tools is shown in demos whereby they part off a railroad rail and sledge hammer head. Talk about significant interrupted cuts…

Read MoreSystem Enables Fast Fixturing

Carr Lane Manufacturing’s latest 768-page catalog features its Carr LockTM products for fast fixturing.

Read MoreIndexable Mini Angle Head Enables Multi-Position Machining

Eltool's indexable mini angle head can mill and drill in bores or cavities as small as 5/8" in diameter.

Read MoreOnline Marketplace for Surplus Tooling

Industrial Surplus Solutions has launched toolingmarketplace.com, an online resource to facilitate the buying and selling of surplus cutting tools.

Read MoreVMC Equipped with FSM for Unattended Operation

Okuma will display its vertical machining center equipped with a Palletace flexible manufacturing system (FMS) for unattended operation.

Read MoreWebinar: Increase Milling Output on Your Existing Machine

It is not always the strength of the tool or the power of the machine that limits your depth of cut. In many cases, the limitation is the tendency to vibrate. Learn how to mill more productively by selecting spindle speeds tailored to your machine’s dynamics.

Read More