Ultrasonic-Assisted Machining with Standard Machines and Tools

A system to be marketed in 2015 will apply ultrasonic vibration from within the toolholder to reduce cutting force and improve the performance of the cut.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

A drill or end mill within a machining center spindle sees two types of movement. The spindle rotates the tool and the machine axes feed it. We have no expectation for the tool except that it will be driven through the material by these two motions alone.

However, what if the tool itself was also moving in a way that complemented these motions, increasing the effectiveness of the cut?

Manufacturing R&D firm EWI of Columbus, Ohio, has been exploring an answer to that question. A system developed by this group applies a controlled ultrasonic vibration to a standard cutting tool, causing the tool to expand and contract through a microscopic amplitude. Experiments have shown that the resulting movement of the cutting edge enables the tool to cut more effectively, passing through the material with less force. The improvement is so great that, for example, a combination of machining center and drill that was formerly unable to complete a hole in a 1.5-inch-thick titanium plate can now get several holes per tool whenever the ultrasonic oscillation is powered on. The system delivering this oscillation will be available for sale in 2015.

“Acoustech” is the brand name for this system. Though the system realizes ultrasonic machining, EWI avoids this term, which has come to be associated with a different and more established technology. Usually, “ultrasonic machining” refers to specialized ultrasonic machine tools that oscillate an abrasive tool. EWI’s offering is not that. The Acoustech system makes use of controlled ultrasonic vibration not on a special machine tool, but on any existing machining center using any standard drill or end mill.

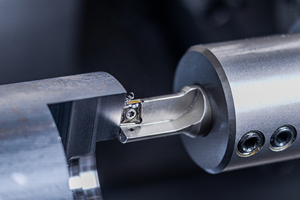

The vibration comes from a device that is essentially a toolholder with an ultrasonic actuator built in. The same device also incorporates a compensating vibration-cancellation mechanism that prevents the ultrasonic actuation from affecting the machine tool itself.

The vibration is “ultrasonic” because its frequency is above what the human ear can hear. Audible noise occurs at 15 to 18 kilohertz. Acoustech vibrates the tool at 20 to 60 kilohertz. The specific effect of this vibration is expansion and contraction of the tool through a controlled amplitude. Trials in aluminum performed by the National Center for Defense Manufacturing and Machining suggest that the ideal size of the amplitude in this material is 5 microns—large enough to have a favorable effect on the mechanics of the cut, but small enough so that the tool’s cutting edge never leaves the chip.

Used with a drill, the Acoustech system causes the tool to lengthen and shorten by this small extent. The effect is much like a 20- to 60-kiloHertz peck cycle. But EWI technology leader Matt Short, who has been involved with Acoustech throughout its years of development, says there is more going on than this. The helix of the lengthening and shortening drill essentially “unwinds” and “rewinds” by a comparable extent. The edge of the helix thus moves forward and back within the cut to a microscopic degree. As a result, the system produces the equivalent of a torsional peck cycle as well, with the cutting edge practically sawing through the material as it goes. A similar effect happens with end mills. Because the tool is repeatedly relaxing its engagement with the cut, friction is less, meaning heat and cutting force are also less and tool life is generally longer.

The difference has been measured in test cuts, and some of the measured performance improvements have been dramatic. In one trial involving drilling holes in 316 stainless steel, the cutting force measured using Acoustech remained less than that of the standard, unassisted cut even after the feed rate for the ultrasonic cut was increased. With the Acoustech system on, feed rate could be doubled, and the measured cutting force was still 13 percent less than what was measured for the slower, standard drilling pass. Ultrasonics also improved the measured surface finish of the hole by 12 percent, EWI says.

In a similar test, the Acoustech system allowed the feed rate to be increased from 7.3 to 14.6 ipm in stainless, but with a tool-life increase because of the cutting force reduction.

In a milling trial involving an end mill held at a high stick-out length, the tool deflected during standard side milling to produce an unacceptable taper in the part. When the process was then run at the same conditions using the Acoustech system, the measured cutting force decreased by 62 percent. This lower force was slight enough that the tool did not measurably deflect, enabling it to mill the surface square.

This cutting force reduction provides for a variety of potential benefits, Mr. Short notes. In addition to the potential improvement in feed rate, tool life and accuracy, less cutting force also means reduced power consumption.

Related Content

Rego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read MoreRego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreThrough-Coolant System Cuts Nickel-Alloy Cycle Times by 70%

Decker Machine Works recently adopted Rego-Fix’s reCool through-coolant system for ER collets, reducing the cycle times on a nickel alloy job by 70%.

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)