Toolholders

Balanced Tool Assemblies Boost Quality, Efficiency

With balancing equipment and shrink-fit toolholders from Haimer USA, this manufacturer of automotive castings improved productivity, accuracy and surface finishes while extending tool and spindle life.

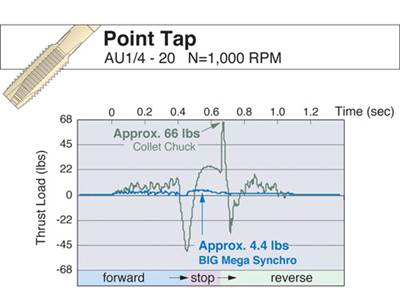

Read MoreReducing Thrust Loads During Rigid Tapping

Some amount of synchronization error is inevitable with rigid tapping. By allowing just a slight amount of axial movement to compensate for synchronous errors, this tapping holder is said to reduce thrust load by as much as 90 percent.

Read MoreHydraulic Expansion Toolholder

The Schunk Tendo-ES is a short, hydraulic-expansion toolholder that allows the tool to be clamped directly in the mounting taper. The tool shank is supported via the spindle, and the result is a high holding force for transferable high torque and additional space in the machining area.

Read MoreToolholder For Aggressive Cutting

Techniks’ DualDrive toolholders, which can be used with all spindles, eliminate the gap between the toolholder flange and the spindle face to provide increased rigidity and accuracy when cutting. The company recommends using these toolholders when high metal removal rates, high feed rates and/or machining at extended lengths is desired.

Read MoreHow Do You Machine a 30:1 Hole in Stainless Without the Drill Wandering?

An expert in micromachining says one answer is to check various aspects of the drilling process. Another answer is not to use a drill at all.

Read MoreRound Internal Toolholder Selection Expands

Thinbit, manufactured by Kaiser Tool Company, has expanded its selection of internal Groove ‘N Turn toolholders. Available in ½", 5/8", ¾" and 1" diameters, the toolholders have a 1.

Read MoreShrink Fit Toolholders Offer Consistent Results

Lyndex-Nikken’s shrink fit toolholders are designed for optimum accuracy, rigidity and balance. The solid construction minimizes unbalance variations when changing cutting tools, the company says.

Read MoreThe Knob Problem

The retention knob is an unmistakably critical component of the machining process. However, the tightening of the knob itself can lead to the toolholder not seating securely in the machine. You may be losing tool life to knob tightness without even knowing it.

WatchVideo: Retention Knob Tightening And Toolholder Deflection

This footage illustrates how the toolholder taper is measured in a test designed to capture the retention knob’s effect on the shape of the toolholder taper.

WatchRotary Broaching Attachments For Swiss Lathes

TPS International introduces the Swiss Broach line of rotary broaching attachments specifically suited for use on Swiss-style lathes. The attachments feature adjustment-free, compact holders for tight tooling spaces.

Read More

.png;maxWidth=300;quality=90)