Toolholders

Slim Milling Chuck Provides High Gripping Force

Big Kaiser has launched the HMCJ, a super-slim milling chuck with peripheral coolant supply, designed to support heavy-duty and finish-end-milling tasks with power and precision using ½"- or 12-mm-diameter cutters.

Read MoreShrink-Fit Chuck for Heavy-Duty Applications Can Replace Weldon Holder

Haimer’s heavy-duty shrink-fit chuck is designed for roughing applications in the heavy machinery and aerospace industries.

Read MoreImproving Tool Life by Turning off Coolant

In this case study, learn how retooling with the Di-Pos Hexa high-performance face mill from Ingersoll Cutting Tools and turning off the coolant helped McGill Machine Works achieve eight times the tool life of its previous inserts plus an 80 percent boost in throughput.

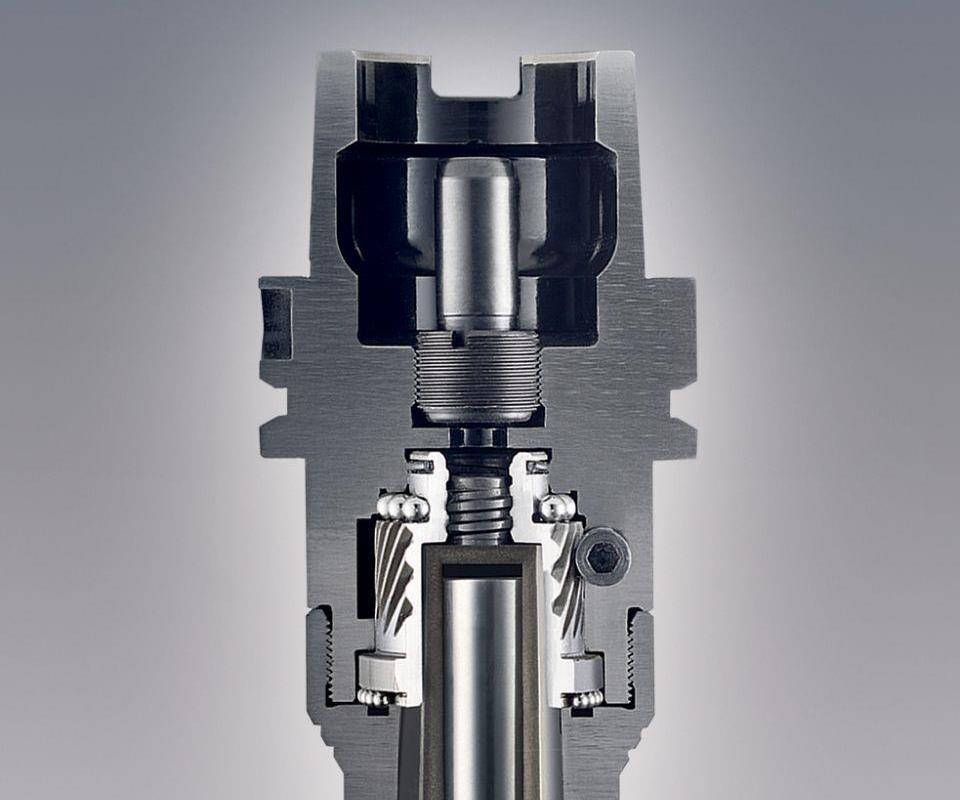

Read MoreHydraulic Expansion Toolholder Transfers 520 Nm of Torque

Schunk’s Tendo E Compact toolholder eliminates the need for different holder technologies for milling, drilling and reaming.

Read MoreOkuma Welcomes Velocity/Briney to Partners in THINC

The new membership of Velocity/Briney brings the Velocity Smart Tool to use with Okuma machines.

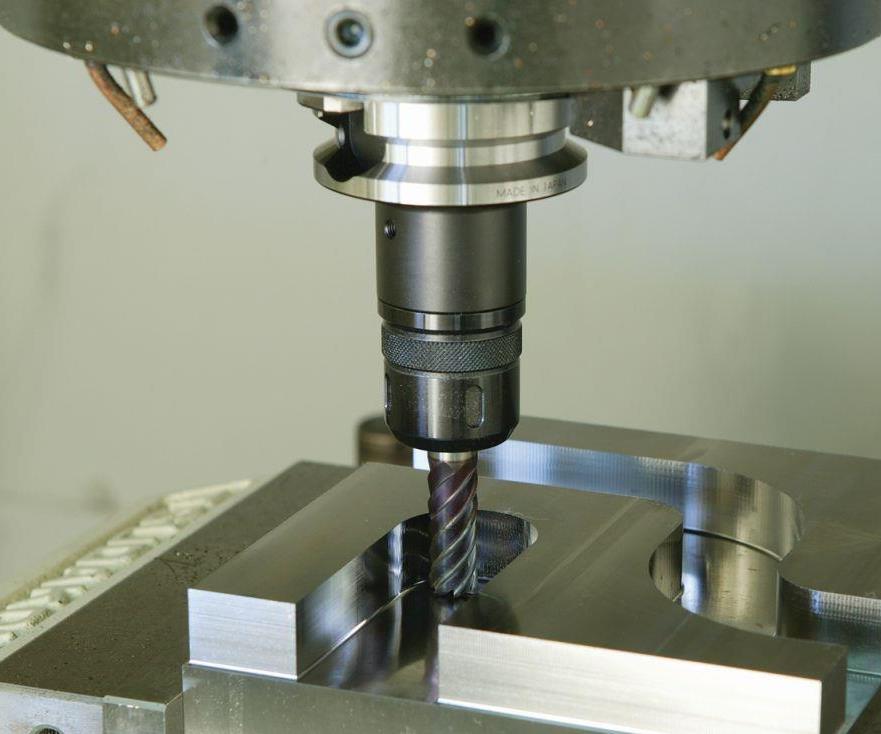

Read MoreMill, Drill Chucks Deliver 3 Tons Traction Force

Emuge introduces its FPC mill/drill chucks designed to improve rigidity, vibration dampening, concentricity, machining speed and tool life compared to conventional chucks for milling and drilling.

Read MoreOptimized Machining out of the Box

Four tooling-related companies partner to supply dynamically stable milling for improved productivity on existing machine tools. Users do not have to measure the dynamics of their machines. Instead, tooling tailored to the machine arrives as a complete assembly, along with software for quickly determining the parameters that tooling can be used to achieve.

Read MoreRego-Fix Breaks Ground on New Headquarters

The new facility will house the company’s sales, distribution and support divisions.

Read MoreExpanded Line of Pre-Settable, Quick-Change Tooling Systems

Göltenbodt, represented in the United States by Schwanog, introduces its new generation of toolholders for Tornos MultiSwiss 6×4 and Star Swiss-type automatic lathes.

Read MoreInside Haimer’s Expanded North American Headquarters

The company’s shrink-fit, balancing and tooling technologies are on display in a new 25,000 square-foot facility.

Read More

.png;maxWidth=300;quality=90)