Optimized Machining out of the Box

Four tooling-related companies partner to supply dynamically stable milling for improved productivity on existing machine tools. Users do not have to measure the dynamics of their machines. Instead, tooling tailored to the machine arrives as a complete assembly, along with software for quickly determining the parameters that tooling can be used to achieve.

Share

Every milling process has a spindle speed, or a set of spindle speeds, at which it inherently wants to cut. Run at one of these particular speeds (the “sweet spot,” if you will), and chatter quiets down. Heavier cuts are possible. Higher tool life is achieved. Particularly above 10,000 rpm, the chance for enhanced cutting performance at these dynamically stable spindle speeds can be pronounced. Finding and running at these speeds is perhaps the most accessible productivity enhancement that hardly any shop is using.

Why are dynamically stable milling speeds not more widely used? The corresponding organizational complexity is part of the reason. Those seemingly magical spindle rpm values are different for every different combination of machine, toolholder, cutting tool and tool overhang length. Finding the right speed for one combination is not difficult—a measurement using commercially available frequency-analysis equipment can determine it in minutes. (Involving a tap with a small hammer, this measurement is commonly called a “tap test.”) However, the shop that is intent on using stable speeds has to determine this ideal speed for every combination of machine, tooling and stick-out length that it wants to optimize. It also has to apply the discipline to ensure that tools and toolholders are always assembled the same way and assigned to the correct machines, and that the machining cycles always use the correct spindle speed for each machine-and-tooling combination. All in all, this is more preparation than most shops are willing to make, and it is more process control than they are able to realize.

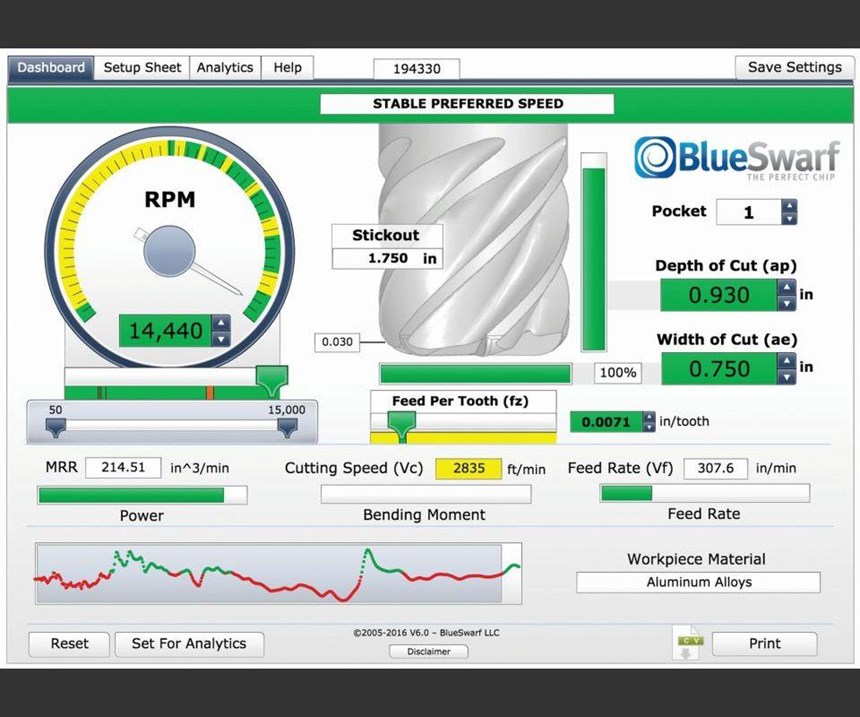

It would be better if there was simply a way to purchase the productivity enhancement. Yet the hope of delivering dynamically stable speeds that easily has proven elusive. Since the speeds are dependent on individual machine and tooling choices, there has never seemed to be a way to provide those speeds as an out-of-the-box product. The company BlueSwarf, for example, has wrestled with this. This firm provides a software interface—its “Tool Dashboard”—that makes use of machining stability signatures by allowing users to quickly find the most productive parameters for a given machine-and-tool system in a given workpiece material. Yet BlueSwarf still requires its users to have performed a tap test, or to have something equivalent to tap-test data for the machining system.

But now, thanks to a partnership involving other tooling-related companies—and thanks to a business model that they are pioneering together—the prospect of simply purchasing an optimized process has come much nearer to reality.

The companies include BlueSwarf, along with Briney Tooling Systems, Fullerton Tool Co., and the Morris Group business unit Velocity Products. The product they have introduced together is the “Smart Tool” system now supplied by Velocity. The system works this way: For any machining center from Okuma (more on that requirement later), Velocity will provide a complete tooling assembly that is optimized for high-productivity milling on that machine. The assembly consists of a Briney toolholder tailored to that machine’s dynamics, as well as the user’s choice of Fullerton end mill and a custom tool overhang length selected to optimize the dynamic resonance of this overall machine-and-tooling combination. This assembly (with retention knob) is balanced as a unit and sent in a package that also includes a BlueSwarf Tool Dashboard tailored to that assembly, allowing the user to quickly determine the optimum combination of spindle speed and depth of cut in various applications. The result is optimized milling out of the box, without users having to perform any of their own frequency measurements, and without the user having to implement much in the way of new process disciplines or controls.

The extent of performance improvement will vary, but the Smart Tool group says a doubling of productivity from heavier depths of cut and doubled tool life from smoother cutting are reasonable outcomes compared to the non-optimal milling conditions at which many shops typically run. To be sure, slight process controls are needed to achieve and maintain these results. Toolholders optimized for a particular machine need to stay with that machine, though they can be used with any of the Smart Tool assemblies that might have been purchased for different end mills on that machine. Also, the end mills need to be re-ordered through Velocity—which obtains them from Fullerton—in part because these companies will ensure that the correct overhang length is maintained. In this system, the overhang is controlled by the placement of a patent-pending custom setscrew slot in the shank of the tool. The customer order number for any individual Smart Tool assembly cues Velocity and Fullerton to the accurate placement of the slot for that particular customer’s tooling.

The Smart Tool system is only available for Okuma machines. Velocity supplies tooling and accessories for Okuma equipment, but other factors led to the focus on this builder as well. Research done by Tony Schmitz and Scott Smith of the University of North Carolina at Charlotte (near Okuma’s U.S. headquarters) enabled this system, because it led the way for combining tool and machine frequency responses mathematically rather than measuring every combination. And BlueSwarf, as a member of Okuma’s “Partners in THINC” network, had sufficient access to the company’s machine tools to be able to perform the necessary measurement of their dynamic properties. (Meanwhile, perhaps fittingly, all Briney toolholders happen to be made on Okuma machines.)

One other point Velocity and the other Smart Tool companies take care to point out is this: The system is entirely U.S.-made. In other words, for companies favoring domestic manufacturing, the system is optimized in this way as well. Fullerton and Briney both do their manufacturing in Michigan, and BlueSwarf is also a U.S. firm. In this case, therefore, the claim that the best tool for the job is made in America is an assertion that can be supported with the physics and the mathematics of frequency analysis.

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreHow to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)