Oil & Gas

Slotting Out A Niche In The Oil And Gas Industry

Designed for accurate slotting and grooving, Iscar's Tangslot cutter features tangentially mounted inserts that are said to improve tool life and chip evacuation. This tool was just what one Texas shop serving the oil and gas industry needed to reduce production costs and increase efficiency.

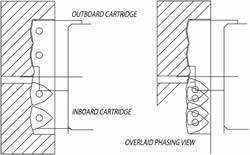

Read MoreNew Boring Tool Phases Out Multiple-Pass Operation

Boring large holes often takes multiple passes that lead to lengthy cycle times. This oil industry manufacturer turned to Allied Machine and Engineering for help with one such troublesome application. A custom tool saved the shop hours on cycle time.

Read MoreAutomated Production Of Oil-Drill Couplings

A machining cell combines lathes, a robot and a conveyor system to enable automated production of precision oil-drill couplings.

Read MoreThe Case For Hydrostatic Ways

Moving on oil can let a grinding machine deliver more power along a smoother pass.

Read MoreMeasuring Big: Lessons From The Oil Industry

In the world of oil drilling, there are some pretty big things. It's not just the rigs anchored out in the ocean that are huge: Everything that goes along with them seems to get supersized, including the need for gaging.

Read MoreOil Drill Coupling Production Gets Automated

Sponsored by Okuma. A manufacturing cell combines lathes, gantry robot and conveyor system to enable automated production of oil drill couplings.

Read MoreCycle Shop Streamlines Startup With CAD-CAM

This start-up motorcycle manufacturer is an offshoot of Lucas Oil, a private oil marketer that supplies truckers, auto-racers and bike racers with oil formulations that are designed to offer protection while enhancing engine performance. Having already attended bike shows and racing events with its own promotional motorcycle, the company says it felt that introducing its own line of bikes and apparel seemed like a logical brand extension.

Read MoreSoftware Switch Leads To Improved Surface Finishes

MSI Products, a division of Dixie Iron Works (Alice, Texas) faces the challenge of building products with complex geometries for the oil- and gas-producing industries in relatively low volumes. The company struggled with programming software that was not able to import the complex assembly models needed to define its products or fully support the functionality of its CNC machine tools. This meant programmers had to define machine movements with lines of G code.

Read MoreSimplfying Thread Repair

Repairing damaged or worn threads on a workpiece is a common chore for toolroom lathes, especially in the oilfield industry. Haas Automation has a new feature for its conversational control units that simplifies and automates this process.

Read More