Oil & Gas

The Big Niche

Expertise and the right equipment for machining large components for oilfield and other industries enable this shop to succeed despite fluctuating economic conditions.

Read MoreSoap For Machinists

Developed for machinists to prevent skin irritation resulting from contact with metalworking fluid, Uncle Earl’s Soap for Machinists is formulated to remove shop grease, oils and grime. Produced by Zebra Skimmers, a manufacturer of oil skimmers and fluid maintenance equipment, the soap is designed to alleviate dry, cracked and burning hands—a common problem associated with the use of metalworking fluids—without the use of abrasives or barrier creams.

Read MoreTwin-Spindle, Twin-Turret Turning Center Boosts Pump Manufacturer’s Productivity

Precision Downhole Pumps, a division of Cameron International, in Iola, Kansas. is using two twin-spindle, twin-turret turning centers with Y-axis milling capability to finish complex jobs in one setup instead of the six formerly required. The new machines, from Doosan Infracore, have reduced manufacturing time by more than 30 percent.

Read MoreWebinar Presents Oil-Skimming Basics

Abanaki Corporation offers “Oil Skimming 102,” an online video tutorial about selecting the right oil-skimming product. The tutorial presentation is adapted from the company’s “Oil Skimming Facts Tutorial Handbook.

Read MoreThriving By Honing The Hard Stuff

Advanced machines, a healthy tooling supply and years of experience allow a Texas shop to take on honing jobs that others simply can’t do. A good portion of that complex work is tubes for offshore oil rigs. These components require bores that must maintain straightness and accuracy over lengths approaching 50 feet.

Read MoreCNC Machine Fire Suppression System

The company’s automatic fire suppression systems are suited for CNC machines that use oil-based lubricants, which can overheat, ignite and cause a flash fire. Featuring a flexible polymer tubing that ruptures when exposed to a flame, these automatic systems detect and suppress a fire by flooding the machining area with a suppression agent and turning the power off. The machine can be returned to service within an hour.

Read MoreGrinding Oil Improves Surface Quality

Blasogrind HC 5 from Blaser Swisslube is a high-performance grinding oil based on synthetic oil (hydro-racked oil). Applications include precision tool grinding, surface grinding, cylindrical grinding, fine profile grinding and lapping. Materials include steel; hardening and tempering steels; high speed steel; hard alloy; stainless steel; and carbide.

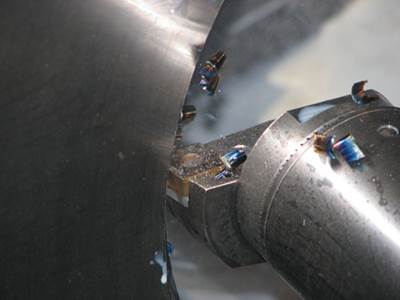

Read MoreInsert Provides Long Life, Short Cycle Times

Novatek, a manufacturer of diamond products used in the oil and gas, mining, construction and other industries, needed to reduce both costs and production time on a job involving very large workpieces. The Tiger-Tec black and gold WPP10 insert from Walter USA, which features an aluminum oxide coating designed to prolong tool life at high surface footages, helped the company increase feeds and speeds and create smaller, more manageable chips.

Read MoreYour Liquid Capital—A Dire Emergency

This article was written while “burning the midnight oil” because about 95 percent of this column’s readers who call me have a significant portion of their wealth being pummeled by the Wall Street meltdown.

Read MoreRing Groove Cutter Line

Designed specifically for the oil and gas industry, Greenleaf Corporation’s expanded Ring Max line of ring groove tooling is suited for difficult to machine materials. Combined with the company’s WG-300 or WG-600 whisker-reinforced ceramic inserts, the ring groove cutters can reduce cutting times from 30 min. to less than 1 min.

Read More