Metalworking Fluids

About Metalworking Fluids and More

Two science papers from Quaker Chemical Corp. are worth reading for what they say about key developments in metalworking technology.

Read MoreHeavy-Duty Machining and Grinding Fluid

Quakeral 372 is a high-performance emulsifiable metalworking fluid from Quaker Chemical designed for heavy-duty machining and grinding operations.

Read MoreDeep Bed Gravity Technology Enables a Variety of Filtration Levels

Mayfran International says its Hydrostatic Paper Filter combines high levels of chip removal with coolant filtration to improve the productivity of the high-performance metalcutting and finishing machine.

Read MoreMetalworking Solution for Difficult-to-Machine Materials

Tech-Cool 35052 is a premium-grade, chlorine EP-activated, semi-synthetic metalworking fluid formulated for titanium (Ti6Al14V), high nickel alloys (including Inconel and Hastalloy), aluminum alloys (cast and wrought) and ferrous substrates.

Read MoreTool-Related Considerations for More Efficient Machining of Titanium

The expert in our Titanium Machining Zone offers advice related to coolants and coatings.

Read MoreCO2 Processer Unit

The company’s CPU (CO2 Processer Unit) provides OEMs, machine builders and equipment engineers with advanced CO2-based processing technology for cleaning, machining and thermal spray in a compact Plug-and-Spray integration module.

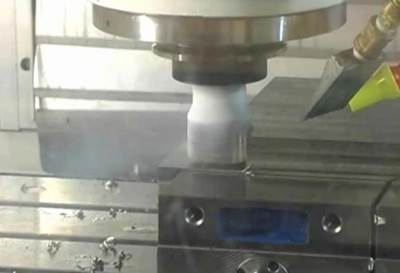

Read MoreVideo: Cryogenic Machining of Titanium

Through-tool liquid nitrogen turns the tool into a heat sink, extending tool life.

WatchThe 400° Difference

Cryogenic machining achieves dramatic tool life gains not by flooding the cut, but by refrigerating the tool.

Read MoreLong-Lasting Coolant Reduces Costs, Downtime

This shop provides a case in point of the substantial savings that can be realized with the proper coolant formulation. Rustlick Ultracut Pro, available from ITW Rocol North America, lasted twice as long in the sump than the shop’s previous coolant, leading to significant operating and maintenance cost savings.

Read MoreThe Many Ways Ford Benefits from MQL

Clean machining using minimum quantity lubrication has allowed Ford’s Van Dyke transmission plant to become fundamentally more efficient and effective at manufacturing six-speed automatic transmissions.

Read More