Metalworking Fluids

Removing Unwanted Oil—in Coolant or in the Gulf

Abanaki’s Fuzzy2 material is being put to work off the coast of Louisiana on a disk skimmer cleaning up oil from the Gulf oil spill.

Read MoreFilter Extends Cutting Fluid Life

Prab/Monlan’s paper bed filter is designed to extend the life of cutting fluids by removing solids from industrial process liquids.

Read MoreCutting Tools, Fluids For Aerospace Machining

Cyclo Cut cutting tools include indexable milling tools, rotary cutting tools and toolholders for roughing, semi-finishing and finishing operations.

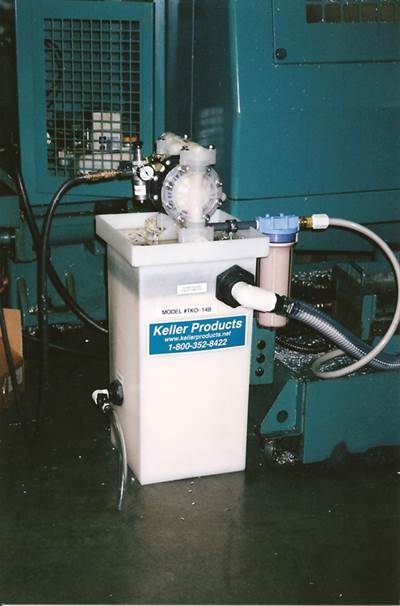

Read MoreCoolant Filtration Yields Significant Savings

While many shop managers intuitively understand the importance of properly maintaining coolant, it's likely that few have calculated the actual cost savings of doing so. Keller Products says the 80-percent savings realized by one customer after installing pump/skimmer units is typical.

Read MoreCYCLO COOL Advanced Technology Fluids

(Sponsored Content) The metal manufacturing industry is dynamic and evolving toward medical and aerospace titanium machining applications. MAG’s CYCLO COOL Advance Technology Fluids are meeting the titanium machining challenges with CYCLO COOL 5000. This unique metalworking fluid exceeds conventional cutting fluid lubrication capabilities and is proven to reduce tooling cost and increase production.

Read MoreCYCLO COOL 900 Series

(Sponsored Content) MAG’s CYCLO COOL 900 cutting fluid series has a unique formula that performs well within the aerospace industry in replacing typical soluble oils and semi-synthetics. These fluids provide huge cost savings in reducing non-scheduled cleanings, fluid maintenance and usage of MWF additives. Customers are also able to recycle these fluids without excessive amount of maintenance, equipment and additives.

Read MoreCost-Cutting Coolant Quells Odor, Dermatitis

Switching to Dyna Cool K2002, a semi-synthetic metalworking fluid, eliminated this shop’s difficulties with coolant odor, short sump life and dermatitis.

Read MoreApplying Minimum-Quantity Lubrication: 3 Articles and a Video

These three articles and a video explain why shops should consider minimum quantity lubrication.

Read MoreFiltration System Sifts Out Costs, Cycle Time

This lapping and grinding shop recently moved into fine grinding (otherwise known as flat honing). A filtration unit from Transor Filter ensured its new fine grinding machine could provide the fine surface finishes and tight tolerances for which it was designed.

Read MoreCYCLO COOL Cutting Fluids

(Sponsored Content) CYCLO COOL cutting fluids consist of a large range of premium metalworking fluids designed for the various dynamic metal manufacturing industries. More specifically, general job shop manufacturing facilities are extremely impressed with the ‘work horse’ nature of CYCLO COOL 1800 and CYCLO COOL 2000.

Read More

.jpg;maxWidth=300;quality=90)