Measurement

Low-Cost, Production-Oriented CMM

The Phoenix RB is a shop-hardened CMM for small- and medium-sized parts. With a capacity of 12″ × 12″ × 10″, the system complements the larger Phoenix (20″ × 16″ × 14″) and features bearing, way, and scale protection for shop use. The scales are metal-on-steel structures assuring uniform thermal response.

Read MoreDimensional Metrology Systems Delivers Consistent Measurements

The expanded SmartScope ZIP family of multi-sensor CNC dimensional measurement systems is available in various sizes for a range of applications. The systems use crisp-imaging zoom optics for non-contact video measurement of manufactured parts. The AccuCentric 7:1 motorized zoom lens auto-calibrates with every magnification change for consistent measurements.

Read MoreLaser-Based ID/OD Measuring Instrument

The laser-based Labmaster universal measuring instrument is suited for gage calibration laboratories that need to precisely measure length, OD, ID, pitch diameter, linear displacement and thickness. According to the company, accuracy is maintained via a laser interferometer, a zero Abbé offset design and a large measuring table with center position, pitch and yaw controls. The computer-controlled precision air-bearing slide and gaging fingers reduce operator-influenced errors by maintaining constant force.

Read MoreDigital Ultrasonic Flaw Detectors

The Epoch 1000 series digital ultrasonic flaw detectors combine high performance for conventional portable flaw detection with the power of phased array imaging. The Epoch 1000, 1000iR and 1000i provide conventional ultrasound capabilities for both the standard and advanced-level inspector. The portable instruments can also be integrated into small systems for high speed scanning and single-channel imaging.

Read MoreMeasuring Microscope Designed For Accuracy, Durability

The MM-200 measuring microscope is designed for the general manufacturing, automotive and electronics industries. The compact, easy-to-use microscope features high quality, accuracy and durability, the company says. The built-in digital measuring stage and DRO attach directly to the arm, which reduces the footprint by 50 percent.

Read MoreHandheld Analyzer With Large-Area Drift Detector

Designed for metal alloy analysis, the Thermo Scientific Niton XL3t series with geometrically optimized large-area drift detector (GOLDD) technology is said to bring lab-quality performance to a handheld XRF analyzer. It can also instantly regain lost traceability on materials. GOLDD technology delivers improvements in light element detection, overall sensitivity and measurement times, the company says.

Read MoreVideo System For Tool Analysis

The Model 560 Video permits rapid, precise inspection of virtually all cutting tool geometry characteristics for both new and reground tools. The system uses a series of lenses and a camera to display the image of the tool being analyzed on a video monitor. A Windows-compatible software analysis program is displayed on the monitor where the tool analysis is conducted.

Read MoreThread Inspection Systems Ensure Dimensional Conformance

Portable or bench external and internal thread inspection systems incorporate functional and pitch diameter size measurements for UN, metric, NPT and other thread forms subject to virtually all thread acceptance standards. The company showcases medical, aerospace and automotive applications that demonstrate how its gage thread inspection systems help ensure complete dimensional conformance of essential thread characteristics. They are useful for operations ranging from simple verification of assembly to complete process control systems for safety critical applications.

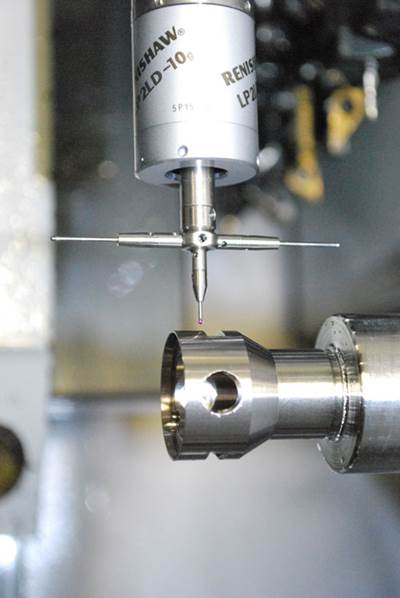

Read MoreProbing Beyond Prismatic

This manufacturer has used on-machine probing to help automate setups and maintain process control for prismatic parts produced on VMCs for years. The metrology products maker recently implemented probing strategies that let it achieve similar results on its turn-mills and Swiss-types. The smaller, more economical batch sizes these machines now produce are better aligned with true production requirements.

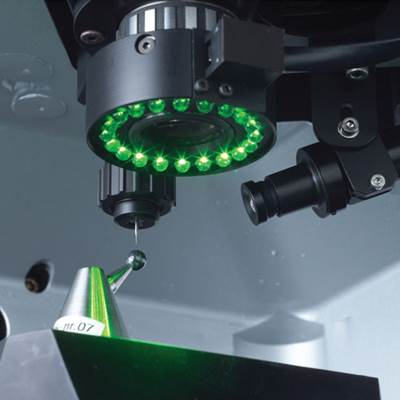

Read MoreMulti-Sensor CMM Eases Micro-Measuring

By combining an optical sensor and a touch probe, the F25 CMM from Carl Zeiss enables users to use the same machine platform to perform metrology operations on a variety of miniature parts.

Read More

.jpg;maxWidth=300;quality=90)