-

SPONSORED

-

-

-

-

Machines

From Manufacturing Circle To Victory Circle

For some time now, this manufacturing company has focused on optimizing engine performance by making ports as efficient as practical so as to reduce turbulence and improve air flow.

Read MoreBreak The Accuracy Barrier

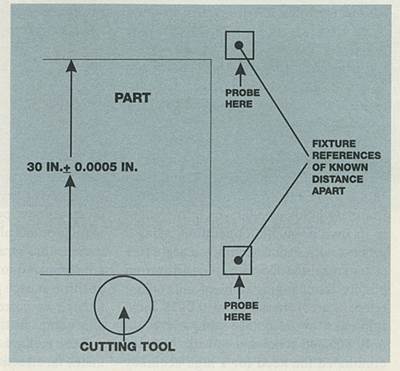

"Reference comparison" uses probing to hold accuracies tighter than inherent process error.

Read MoreHigh Automation for Low Volume

Many people think flexible machining cells are for high production, but this shop finds just the opposite. Here's how they've grown their cell to meet the needs of their work.

Read MoreAbrasive Waterjet Machine For Job Shops

Cutting metal and other materials with a high-pressure stream of water and abrasive grit generally has been the domain of specialty shops dedicated to this process or large plants with special needs—and deep pockets.A new abrasive waterjet machine from Flow International Corp. (Kent, Washington) makes this process as attainable as, let's say, wire EDM, or almost any other mainstream metalworking process.

Read MoreNew Hitachi Seiki Machines Reflect Trends

Any machine tool builder striving to be responsive to customer interests and demands will reflect those interests and demands in the new machines it introduces. A case in point is Hitachi Seiki, which recently introduced a new horizontal machining center and a new turning center.

Read MoreTaking Advantage Of Superabrasives

Using the cutting capabilities of a superabrasive grinding wheel requires a systematic processing approach. It takes more to get good process results than just slapping a superabrasive grinding wheel on a machine tool.

Read MorePower Workholding For High-Flexibility Production

By combining creative fixturing with power workholding, Carr Lane Mfg. Co. has achieved dramatic reductions on the parts setup time, handling time, and transport time between machines. To achieve these results the company selected horizontal machining centers so that the multiple part faces could be machined without

Read MoreEDM And Automation: Not 'Oil And Water' Any Longer

Electrical discharge machining (EDM) was developed in the 1940's, used sparingly for burning out broken taps and dies until the 1970's, then utilized for single part operations, moldmaking and punch-die production in small lots until about ten years ago. This is when the first CNC versions emerged from several manufacturers, including Mitsubishi. Mitsubishi was said to lead primarily because they were the only EDM builder who also built their own machine controllers (through a sister division of the company). Today, CNC and manual machines are still produced, with several thousand units sold each year.

Read MoreDoubling Accuracy Of Manual Grinding Machines With CNC Wheel Dressers

Retrofitting older grinding machines with a CNC wheel dresser makes it possible to reduce the total tolerance band on broaching tools produced with the new dressers from 0.0004- to 0.0002-inch.

Read MoreElectrode Mill Hits 36,000 RPM

Today's CNC EDMs burn cavities faster than ordinary milling machines can feed them with electrodes, and so the demand for high-speed graphite machining centers has opened up an opportunity that machine-tool builders have begun to fill.

Read More

– Medium Rectangle (1).png;maxWidth=300;quality=90)