-

-

-

-

-

SPONSORED

Machines

What Shops Want In Machining Centers

This study summarizes a few of the findings in a newly released report on CNC machining center buyers. The 233-page report focuses on the perceptions and priorities of this group

Read MoreCutting Time

This company modified its production process to cut not just metal, but also setup time, costs and the effects of the labor crunch.

Read MoreEDMing Beryllium Copper: An Introduction

Beryllium copper offers many benefts to the moldmaker and plastic injection molder, yet questions remain on how to best EDM it, which alloy to specify, where to use it, and is it safe to work with?

Read MoreAutomating Multiple Face Machining

Although multiple face machining in a single setup is possible with four-axis machines, these machines only meet the positioning requirements for a small range of parts. To have the capability for programming multi-plane machining-and to machine this type of part in a single setup-a five-axis machine is necessary.

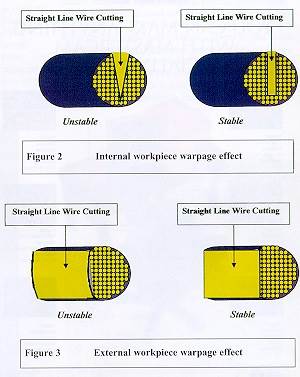

Read MoreCryogenic Treatment Enhances Stability For Wire EDM Operation

In the world of Wire EDM professionals, the mission is very similar to NASA's, in minimizing scrap rate and in maximizing quality (i.e. meeting customer specifications). That is the challenge to each Wire EDM operator and tool designer.

Read MoreSmall Shop, Mighty Machines

Multitasking machines capable of completely machining complex, milled and turned parts in a single setup are powering this Chicago-area job shop's growth.

Read MoreLinear Motors Shorten Production Time

Linear motors account for part of the reason why DaimlerChrysler's Stuttgart, Germany, manufacturing facility has been able to nearly double the productivity of machining centers producing automotive cylinder heads.

Read MoreReaching New Depths And Greater Accuracy

Just when you thought high speed machining or hard milling would steal the best applications from ram-type electrical discharge machines, linear motor technology is taking "sinker EDM" to levels unattainable with any other metal removal process.

Read MoreSparking Better Designs

By automating repetitive splitting and electrode-design work, an Ohio mold and die shop spurs creativity and expands EDM applications.

Read MoreMaximum Aluminum: Optimizing Metal Removal Rate in Aluminum with a High Speed Spindle

Speed changes the rules. To maximize metal removal rate with a high speed spindle, follow some fundamental tooling considerations and mill at just the right rpm.

Read More