Machines

CNC Turning Technology Protects Craftsmanship

The consistency and efficiency provided by SNK's Prodigy GT-27 Gang-Tool Lathe enabled this manufacturer of custom, high-end flutes to concentrate more on craftsmanship and less on trivial tasks.

Read MoreTurn-Mill Turns Flexibility From Vision To Reality

A change in focus to lower-volume jobs led this manufacturer to sell its multi-axis screw machine and seek a new, flexible process to avoid tying up its traditional mills and lathes. DMG’s CTX 310ECO V3 turn-mill has helped the shop improve productivity and part quality while reducing labor costs.

Read MoreTwin-Spindle Grinding Machine Increases Productivity

Paragon’s twin-spindle, compound grinding machine, the RTG-100CNC, is designed for enhanced productivity and precision for ID/OD grinding. Clamping once instead of twice, the machine can grind as many as eight faces, featuring maximum an OD of 320 mm and an ID grinding range from 6 to 100 mm.

Read MoreThe Most Valuable Resource For Succeeding At Lean

What is the most valuable resource? The answer is probably obvious: the people. This shop started to succeed at lean manufacturing once every employee got involved.

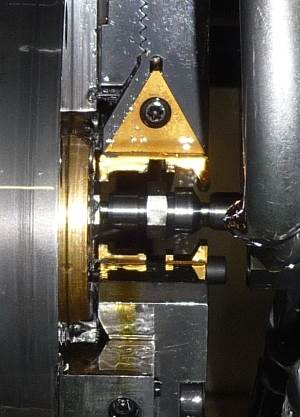

Read MoreVideo: Form Tools On CNC Lathes

Form tools are traditionally associated with non-CNC machines, but in certain applications they make sense on modern machines as well.

WatchVideo: Increased Productivity With More (Not Fewer) Setups

VIDEO. Valve maker Richards Industries took a part that used to machined at one machine tool and added an additional setup on a vertical machining center. Higher throughput was the result.

WatchLaser Scanning Speeds Holemaking Operations

A laser scanning system offers an alternative to touch probing for quickly finding numerous hole positions in heat-exchanger workpieces.

Read MoreCylindrical Grinding Machine Suited For Precise Machining

Lean Selection, a Junker brand, offers the universal external/internal cylindrical grinding machine “silver,” which is designed to produce individual parts or a small series of parts. Suited for automotive manufacturers and suppliers, the silver can be used for applications from general machine construction to toolmaking.

Read MoreFive-Axis Aluminum Machining Centers

Makino’s next generation of MAG series five-axis machinery, the A7, provides increased accuracy and reduced cycle times for large complex aluminum monolithic parts for aerospace structural applications. The A7 is designed with extended X-, Y- and Z-axis travels of 276" × 99" × 40" (7,000 mm × 2,500 mm × 1,000 mm) to accommodate parts as large as 276" × 79" × 28" (7,000 mm × 2,000 mm × 700 mm) that weigh as much as 11,024 lbs (5,000 kg).

Read MoreGrinding Wheel Resists Heat, Wear

During high performance grinding processes, heat builds up in the grinding area. Increasing wear forces weaken the grain and bond structure.

Read More