Grinding

Cutting The Learning Curve

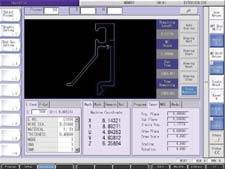

A grinding shop in western Pennsylvania uses self-teaching CNCs to boost productivity.

Read MoreDressing Well: The Key To Grinding Quality

Because the nature of the interface between wheel and workpiece largely defines grinding quality and efficiency, it's essential to maintain optimum conditions within this critical zone. Therein lies the key to sustaining grinding as a competitive process.

Read More

.jpg;maxWidth=300;quality=90)