Grinding

Grinding Wheels for Swiss-Type Screw Machines

MicroSwiss’ say’tec high-performance grinding wheels for Swiss-type screw machines are designed for parts that require tight tolerances, fine finishes and virtually no burrs.

Read MoreGrinding Center Can Accommodate Two Spindles

Emag’s VLC 100 G vertical grinding center is designed for small chucked components with a maximum diameter of 100 mm.

Read MoreSemi-Flex Discs Provide Increased Control

Camel Grinding Wheels (CGW) offers rigid, semi-flex discs for aggressive grinding applications.

Read MoreGrinding and Cut-Off Wheels Require Less Pressure

3M Cubitron II bonded abrasive grinding and cut-off wheels offer precision-shaped grain technology.

Read MoreDiamond and CBN Wheels Provide High-Performance Round-Tool Flute Grinding

Norton Paradigm diamond and CBN wheels from Saint-Gobain Abrasives are designed for high-performance grinding of carbide and round-tool fluting on high speed steel to decrease cycle times and cost per part.

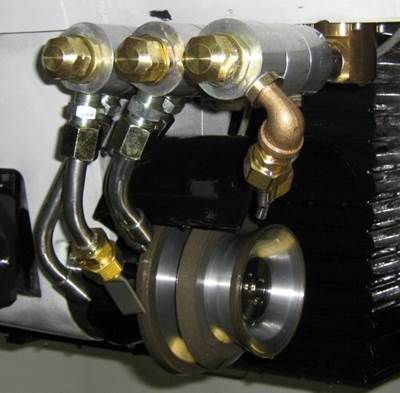

Read MoreHoning Solves Problem in 1/4-Scale Engine

Gary Conley used honing to solve a problem inside a tiny engine.

Read MoreWhere Grinding Still Beats Hard Turning

For many critical applications, grinding remains the optimal machining process.

Read MoreNozzle Considerations

How coolant is delivered to a grinding wheel can greatly impact the overall grinding process.

Read MoreMore Effective Cooling, Lubrication for Grinding

Coherent-jet nozzles offer advantage over plastic and rigid tube nozzles for coolant delivery to grinding wheels.

Read MoreHigh-Performance Centerless Grinding Wheels Lower Abrasive Cost

Gardner Abrasives, part of Cinetic Landis Corp., offers the BDP bond system for centerless grinding applications.

Read More

.jpg;maxWidth=300;quality=90)