Grinding

Surface Grinder's Sealed Spindle Promotes Service Longevity

Kaast Machine Tools’ saddle-style F-Grind AH series high precision surface grinder is said to accommodate workpieces ranging from 5.8" × 17.5" all the way to 15.5" × 31", depending on the model.

Read MoreBuying a Grinder: The Appeal and Construction of a Grinding Machine

The first step to buying a new grinding machine is understanding how it works. Learn more about the makeup of grinding machines, including multi-spindle machines.

Read MoreGrinding Machine Processes Longer Shafts

Liebherr has introduced the LGG 400 M model grinding machine that fits the same footprint as the previous, smaller LGG 280 M.

Read MoreSurface Grinders Said to Eliminate Need for Hand Balancing

Chevalier’s FSG-ADIV series of surface grinders has several new features designed to improve productivity and ease of operation.

Read MoreHow to Calculate Wheel Life in a Creep-Feed Grinding Process

For non-continuous-dress creep-feed grinding, the calculation is straightforward. For continuous dressing, the calculation has more steps, but in either case, it is possible to manage the cost of grinding by predicting the life of the wheel.

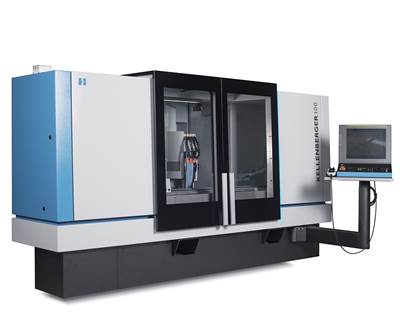

Read MoreUniversal Grinder Offers 10 Wheelhead Options

Hardinge offers the Kellenberger 100, a high-performance, economical grinder for universal grinding.

Read MorePneumatic Die Grinder Accesses Small Part Features

Norton | Saint-Gobain Abrasives has introduced the Norton pneumatic die grinder designed to accomplish quickly and comfortably a range of portable grinding applications without the need to change machines.

Read MoreMounted Grinding Points for Surface and Edge Grinding

Pferd offers an extensive line of vitrified and resin-bonded mounted points designed to meet an array of application needs for use in both surface and edge grinding.

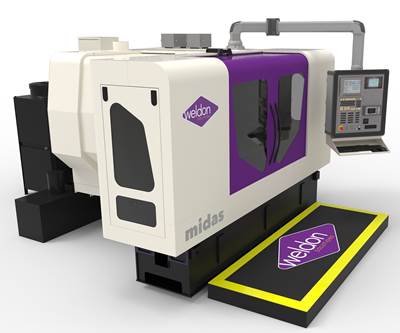

Read MoreGrinder Now Available with Multi-Spindle Turret Wheelhead

IMTS 2018: The reinvented Weldon Midas series now offers an optional multi-spindle turret wheelhead for OD, ID, face, shoulder, radius and taper grinding.

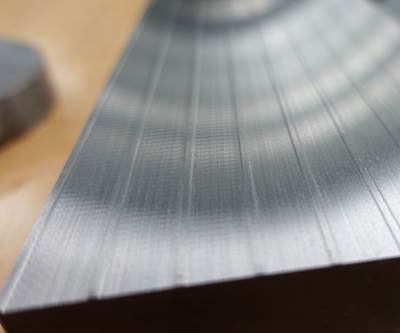

Read MoreHow to Reduce the Effect of Vibration in Production Grinding

It is not always possible to correct a vibration problem as soon as that problem begins to appear. Rather than stopping production, here is a means of continuing to realize smooth, efficient grinding until the underlying cause of vibration can be addressed.

Read More