Grinding

Grinder Lineup Combines Versatility, Simple Programming

IMTS 2018: Supertec Machinery displays its line of machine tools and grinders.

Read MoreFive-Axis Grinder Features Extended Axis Movement

IMTS 2018: Schütte’s 325linear five-axis CNC grinder features extended X- and Y-axis movement and two auxiliary slides for workpiece clamping.

Read MoreGrinder Simplifies Automotive Engine Part Production

IMTS 2018: Meccanica Nova’s Novamatic 2G internal grinding machine grinds multiple bores of an automotive engine component in one work part clamping.

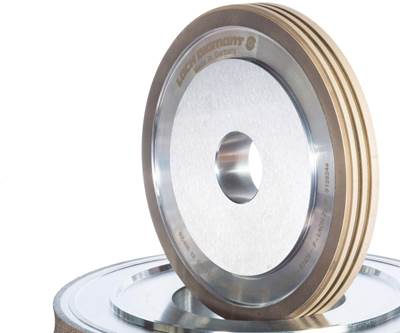

Read MoreContour-Profiled Grinding Wheels Save Time, Increase Tool Life

IMTS 2018: Lach Diamond’s metal-bond, contour-profiled grinding wheels are designed to reduce the number of processing steps during deep grinding of a variety of materials.

Read MoreGrinding Machines Increase Workpiece Space, Enhance Rigidity

IMTS 2018: United Grinding is displaying the Walter Helitronic Power 400 and Helitronic Power Diamond 400 grinding machines, both said to offer 35 percent more workpiece space.

Read MoreRange of Grinding Wheels Provide Higher Profile Accuracy

IMTS 2018: Norton Saint-Gobain Abrasives is displaying its Xtrimium range of gear solutions designed for gear grinding in tight-tolerance environments.

Read MoreFine-Grinding Machines Achieve Precise Plane Parallelism

IMTS 2018: Supfina adds the Spiro F5 and Spiro F12 to its line of fine-grinding machines for the batch mode processing of a wide range of parts.

Read MoreDouble-Disc Grinder Features In-Feed Slide, Linear Rails

IMTS 2018: GCH Machinery’s double-disc grinder features upgrades including a servo in-feed slide, linear rails, an automatic lubrication system and user-friendly controls.

Read MoreFive-Axis Tool Grinder Offers Large Grind Zone, Small Footprint

IMTS 2018: Star SU’s NXT tool grinder is designed for large-machine capabilities with a small footprint.

Read MoreUniversal Grinding Machine Performs Straight, Angular Work

IMTS 2018: Toyoda’s GL4i-Switch universal grinding machine features an adjustable wheelhead for straight and angular applications.

Read More

.jpg;maxWidth=300;quality=90)