Data-Driven Manufacturing

Look Beyond Machine Utilization When Installing a Machine-Monitoring System

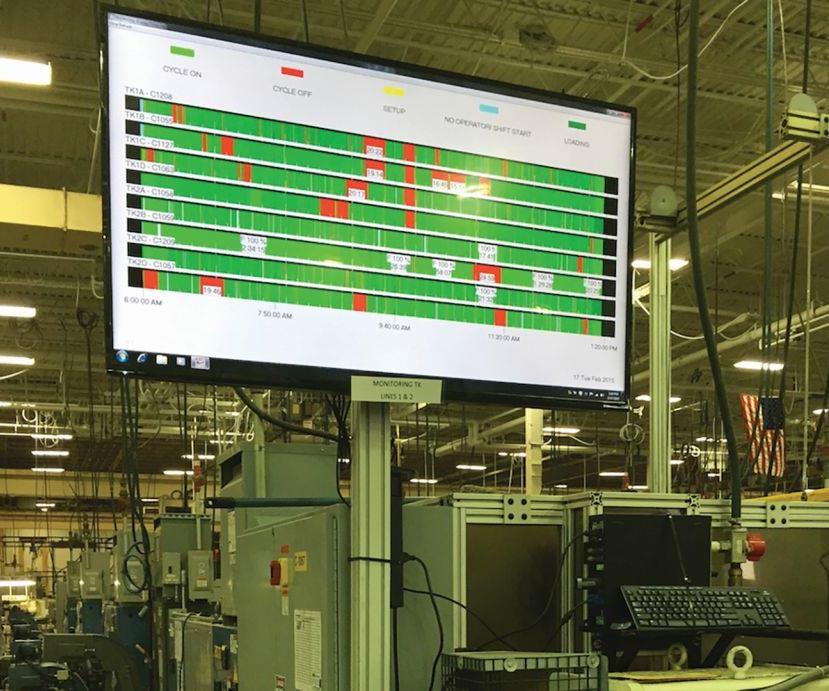

Connecting machines to a network for production monitoring almost guarantees that utilization will go up, but that’s only the first step toward data-driven manufacturing.

Read MoreData from a Machine-Monitoring System Can Help Human Resource Management

Advanced Machining used FactoryWiz from Refresh Your Memory Inc. to go from simply buying more equipment when facing production constraints to becoming more efficient with machine monitoring.

Read MoreMonitoring, Analytics System Diagnoses Pump Operating Problems, Prescribes Solutions

The PumpSense sensor-based system from Prophecy Sensorlytics introduces cost-effective predictive diagnostics technology to alert pump/blower users to developing problems and prescribe timely fixes without any need for outside support, expertise or data analysis.

Read MoreMachine Tool Connectivity Provides Real-Time Performance Data

PMTS 2017: In the dynamic world of Industry 4.0, TechSolve delivers machine tool connectivity and real-time visualization solutions for the manufacturing industry.

Read MoreSpindle Inspection System Helps to Find Root Causes of Failures

Lion Precision’s SpindleCheck Inspector system provides diagnostic and capability data for all rotating spindles to help shops better manage their machine tools.

Read MoreRemote Monitoring System Provides Real-Time Analysis

PMTS 2017: The Smart Attend Pro remote monitoring system features real-time analysis capabilities. It offers dynamic tools for measuring efficiency and making fast, effective decisions from anywhere in the world.

Read MoreTouchscreen Interface Eases Multi-DNC Control, Machine Monitoring

Spectrum CNC Technologies offers SmartTouch, an intelligent machine interfaces that offers touchscreen access to Multi-DNC files and serves as a feedback loop for job status information.

Read MoreDNC: A Growth Path to Machine Monitoring and Data Collection

The connections that enable operators to download tool paths and other files can also be used to report machine status automatically as well as streamline manual entries of production results.

Read MoreDelivering Value Is Key

Machine data requires contextual interpretation to give decision makers a full understanding of what actions are best for optimizing shop floor results.

Read MoreMonitoring Spindle Bearing Health

Caron Engineering’s Tool Monitoring Adaptive Control (TMAC) now has the capability of monitoring spindle bearing health.

Read More

.jpg;maxWidth=300;quality=90)