Cutting Tools

Insert Enables High-Performance Steel Turning

Sandvik Coromant’s GC4325 coated cemented-carbide grade of steel turning inserts provides higher potential for increased cutting speeds and longer, more predictable tool life with high reliability, the company says.

Read MoreSolid Carbide Tools Offered

Destiny Tool’s Solid Carbide Tools Exclusive Preview catalog includes information on its end mills, miniature end mills, cutting tools and special tools.

Read MoreVertical Jig Boring-Milling Machine Enables High Accuracy

Available from Methods Machine Tools, the Yasda YBM 649V3 three-axis CNC vertical jig borer provides high-speed, precision boring and milling for high-accuracy mold, die and complex component manufacturing.

Read MoreHow One CNC Shop Effectively Machines Glass-Fiber-Filled Plastics

You know how to machine metals, but what about plastic machining? More specifically, glass-fiber-reinforced plastic? This machine shop has it figured out.

Read MoreHorizontal Boring Mill Accommodates Large Workpieces

FEMCO’s BMC-110R2 horizontal boring mill features stress-relieved Meehanite castings for all major components and uses induction-hardened boxways on all three axes.

Read MoreMilling Cutters Resist Fracture

Mitsubishi Materials has expanded its AXD4000 series of milling cutters with GM breakers in MP9120 and TF15 grades.

Read MoreMulti-Application Drill Extends Tool Life

The Widia VariDrill multi-application drill is engineered to extend tool life across a range of materials, including steels, stainless steels, cast iron, nonferrous material and high-temperature alloys.

Read MoreQuick-Change Chuck Eliminates Jaw Re-Boring

Schunk’s Rota THWplus quick- jaw-change chuck is designed for flexibility and efficiency in setups.

Read MoreShoulder Milling Series for Steels, Cast Iron

Sumitomo Electric Carbide’s PWS shoulder-milling cutting series handles a variety of materials, including steels, stainless steels and cast irons.

Read MoreA New Formula for Metal Removal Rates in Turning

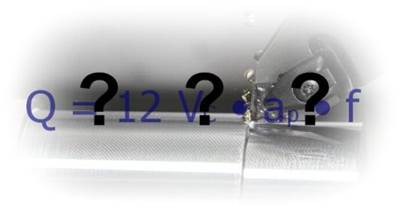

An expert on cutting tool theory and practice is proposing a new formula for calculating the metal removal rates in turning operations. This formula factors in the diameter of the workpiece to yield more accurate results and lead to better decisions about productivity.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)