CNC & Machine Controls

On The Way To Wireless DNC

Any shop with CNC machine tools has probably wondered how a DNC system could be configured to operate with wireless network connections. Wireless systems are being installed in offices, and even in homes, so that laptops, desktop PCs, and handheld devices can communicate via e-mail, share access to the Web, and exchange data.

Read MoreIs Manual Programming Really Important?

I am often questioned about the scope of this column. The most common question is: "Why do you continue to discuss manual programming techniques when almost all companies are using CAM systems?" Aside from the fact that other columnists are addressing issues related to computer integrated manufacturing, I believe that a firm understanding of manual programming is of paramount importance to all CNC people.

Read MoreNetworked Machine Shop Learns The Value Of Proper Grounding

In business for more than 22 years, McAfee Tool&Die Inc., uses conventional machine tools, stamping presses and injection molding machines, as well as more than a dozen computer numerical control (CNC) machine tools, including three 3-axis machining centers, six wire electrical discharge machines (EDM), three laser-cutting machines and a CNC turning center.

Read MoreThe Long View On Short-Run Work

This shop doesn’t know what parts it will machine tomorrow, but it has a good idea who its customers will be well into the future.

Read MoreControlling The Cyber Shop

In recent years, technological trends have taken the form of multi-process machines with sophisticated monitoring and control systems. The ultimate purpose of marrying advanced hardware and software is to achieve a fully automated and more reliable manufacturing process.

Read MoreRacing Team Shifts Into Reverse Engineering

When the Joe Gibbs Racing team went shopping for a reverse engineering system five years ago, it looked at a variety of technologies. But the team decided to put this on-machine scanning system in the driver's seat of its reverse engineering program.

Read MoreControl Helps Museum Fill In The Gaps

Today, with Hollywood leading the way in the precise, high tech creation of real and imaginary forms, anything seems possible, such as bionic people, dinosaurs or extra-terrestrial beings. But the final machining of the prototypes, molds and net shapes of these forms is still being done the 'old-fashioned' way with lathes, mills, grinders and routers.

Read MoreControl Keeps Press Manufacturer Competitive

The Web Press Division of KBA North America Inc. (York, Pennsylvania), a builder of high speed presses for newspaper printing, recently investigated its need for improved control in the production of parts used in its equipment construction.

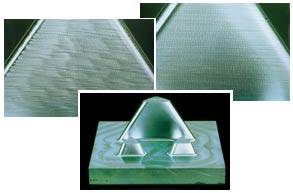

Read MoreCurve Interpolation For Less

When the CNC executes the program faster, a higher feed rate becomes possible. Precisely this benefit has compelled many mold makers in particular to inquire about NURBS.

Read MoreFinding The Current States Of Your Control

You probably know that most current CNC controls will display all currently instated modes (commonly set by G codes). With one popular control, this is part of the program check display screen function.

Read More

.jpg;maxWidth=300;quality=90)