CNC & Machine Controls

Eldorado Gundrilling Machines Get New Control Panel

Kays Engineering’s Eldorado gundrilling machines feature an updated operator control panel.

Read MoreAthena Reduces Time and Investment Required to Train Novice Machinists

EMO 2019: Athena is a universal, voice-operated assistant technology specifically designed for manufacturing work.

Read MoreFANUC's 0i-Model F CNC System Enables Program Simulation

Westec 2019: FANUC’s 0i-Model F CNC system and a servomotor cart controlling motion and movement comprise a FANUC CNC training simulator.

Read MoreNews of Note: July 2019

New options for training young folks, NTMA offers blockchain services, a new partnership promoting additive manufacturing in aerospace work, and other industry news.

Read MoreMitsubishi Offers CNC Total Care Package for Maintenance Needs

The Total Care Package provides maintenance by combining three existing services: CloudCNC backup, machine tuning and preventative maintenance.

Read MoreHeidenhain's TNC-CNC Academy Offers Training for Users of All Levels

The company states that completing these classes will allow TNC users to improve efficiency and accuracy of the parts they machine.

Read More5 Things New CNC Machine Operators Must Know

These subjects are the building blocks of training newcomers on a specific CNC machine tool.

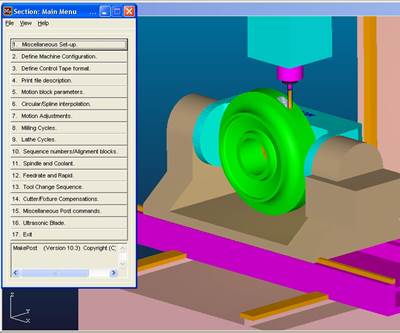

Read MorePostWorks 17.2 Generates NC Code for Variety of Machines

NCCS Corp.’s PostWorks 17.2 is a universal postprocessor that generates NC code for a variety of machines.

Read MoreMonitoring Time for Preventive Maintenance Tasks

Not all maintenance tasks should be performed based on a calendar date. You can use a custom macro to monitor your machines.

Read MoreSiemens and Comau Collaborate to Offer Sinumerik CNC Incorporating Robot Control

Through a cooperative agreement, Siemens and Comau now offer a jointly engineered Sinumerik Run MyRobot DirectControl product.

Read More