Software Aids Transition To Production Mindset

Over the years, aerospace manufacturer Costa Precision has developed a reputation for taking on large, complex parts that other shops can’t handle. However, overly optimistic customer expectations and lengthy cycle times led Costa to struggle with generating revenue on the manufacturing side of its business. With a new production-oriented mindset and CAD/CAM software from Mastercam, the shop was able to maintain the high precision for which it is known while improving manufacturing efficiency and profitability.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreThe ability to competitively manufacture highly complex precision parts goes only so far when those parts can’t be delivered to customers in a timely manner. To be successful, shops must balance the desire to keep manufacturing capabilities ahead of the curve with practical concerns about whether all the pieces are in place to make a return on a job. Aerospace manufacturer Costa Precision recently struggled with and attained this balance. In addition to a new mindset about production, Mastercam CAD/CAM software turned out to be an indispensable tool for continuing a tradition of manufacturing parts that others won’t touch while improving lead times and machining profitability.

Several years ago, management at the Claremont, New Hampshire-based company came to the stark realization that despite an excellent reputation, an experienced staff and 18 high-end CNC mills and lathes, profits were diminishing. While the engineering aspects of the business were still generating revenue, shop overhead and long machining times had reduced cost effectiveness on the manufacturing end. "To make matters worse, our on-time deliveries had fallen into the 60 percent range, which was totally unacceptable," says John Mack, chief operating officer. Ironically, Costa Precision’s core strength—its ability to bid on difficult work that other shops were unable or unwilling to undertake—was driving down profits.

The company needed to make a change, and management initially considered shutting down manufacturing operations entirely. The eventual solution might be considered counterintuitive—the company would further emphasize its strength in manufacturing large, complex parts. This time, however, it would approach all work with a production mindset, whether a contract called for manufacturing a few parts or thousands. In keeping with this new philosophy, the shop stopped soliciting prototype work unless it eventually led to a full production order. "Now, when we grapple with our customers’ most difficult parts, we concern ourselves not only with how we are going to make it, but also how we will make subsequent parts faster, cheaper and on time," Mr. Mack says. "I also think our production manufacturing mindset has made us an even better complex-part manufacturer."

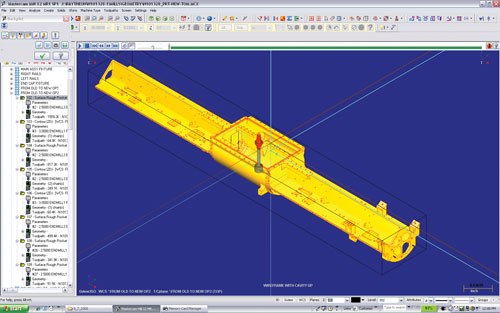

One example of a typical Costa Precision project is a single-piece aluminum body for Raytheon’s AN/ASQ-235 Airborne Mine Neutralization System (AMNS), a helicopter-deployed system designed to neutralize anti-shipping mines. The end product consists of two hydrodynamically stable bodies that look like torpedoes with fins. This complex component begins as a single 10-foot-long, 3,500-pound aluminum billet. Roughing this workpiece takes hundreds of hours, after which the part is shipped across the country for straightening and heat treating. After several hundred more hours of machining, so much material has been removed that two operators can easily lift the part from the large vertical mill by hand.

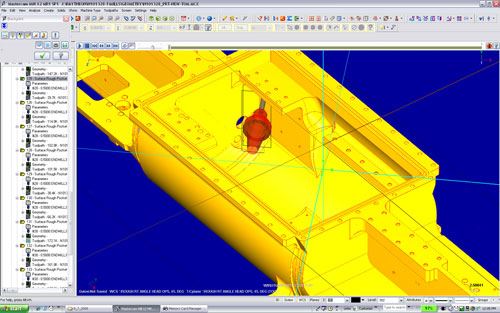

According to Todd Milo, production manager at Costa, Mastercam CAD/CAM software has made a major difference in the company’s efforts to shorten cycles on such time-consuming components. The company has six seats, including X2 Mill Level 3, Lathe and Multiaxis. CAD models come to the shop in various formats, all of which are seamlessly translated into Mastercam. Mr. Milo says the software’s work coordinate system saves time by allowing users to generate programs from dozens of different orientations without having to create new views of the part. The software can also simulate the manufacturing process after part programming to accurately predict machining time and keep projects on schedule.

Mastercam also offers a number of toolpath strategies that reduce total machining time. These include high speed machining tool paths, which Costa used to cut hours off the lengthy roughing operations required for the Raytheon component described above. Throughout the development phase of this product, Programmer/Special Projects Manager Thomas Barber worked with Mastercam to select tool paths that could safely adjust feeds and speeds according to the cutter’s engagement with the material. The result was minimized air cutting and optimized material removal.

Since finalizing the design, Mr. Barber has begun another round of tool selection evaluation and toolpath optimization. He believes that with Mastercam’s process optimization capabilities, he can trim a hundred or more additional hours out of the process.

Mastercam has helped the shop not only reduce machining time, but also ensure that it maintains its reputation for high quality and precision. The Raytheon project provides an example of this as well. With no reworking allowed, there is no room for error on this costly part. One tool slip could cost the company the rough equivalent of two expensive automobiles, not to mention the fact that delivery could be delayed by as long as 10 weeks.

The machine used to cut the Raytheon component is equipped with a fifth axis that accommodates 90-degree and multi-angle heads used to machine shelves and to drill and tap within cavernous spaces. To avoid scrapping the workpiece, Mr. Barber uses Mastercam to create tool paths that minimize clearance issues. Additionally, the software’s verification features enable him to visually ascertain that stock has been removed appropriately from these spaces and that tooling and head clearances are adequate. Moreover, the types of tool paths and the sequence of machining operations selected in Mastercam helped prevent bowing in the part surface, a common occurrence when machining large, complex components from a single aluminum billet.

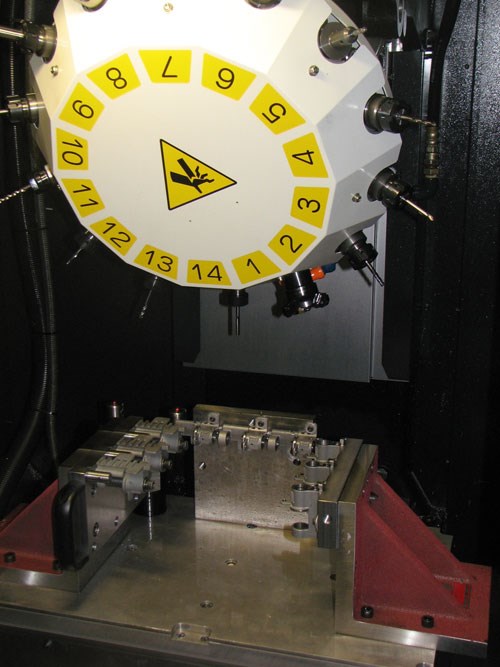

The shop’s new philosophy—applying its difficult part know-how to not only the part itself, but also the cost-effectiveness of the process as a whole—also led it to depart from its core focus on large workpieces. Sitting in one corner of the plant in the shadow of a large, expensive HMC are three small, relatively inexpensive VMCs arranged in a manufacturing cell. Designed by Mr. Barber and the project’s lead engineer, Steve Leclair, the cell is used for the manufacturing and assembly of five parts into a critical firearms component.

The three VMCs, all operated by one person, perform eight manufacturing operations on cast workpieces for one of the components. Programmers used Mastercam to create custom workholding fixutures designed to allow optimal tool access. Meanwhile, machining simulation helped create staggered cycles that give the operator enough time to load/unload each machine and to perform hard gaging and recording of SPC data. At any given time, there are 24 in-process parts in the cell, with three completed every 26 minutes.

In keeping with its new production mindset, Costa partnered with the firearms manufacturer to develop this machining process. The low cost of the equipment and labor reduced the cost of each part while also allowingCosta to maintain profitability. Meanwhile, the Mastercam-designed fixtures allowed the company to machine as many parts as possible in a limited workspace, further improving efficiencies and enabling the company to purchase smaller, relatively low-cost VMCs. This approach resulted ina quality component delivered at a fixed price that was lower than the firearms manufacturer could likely have achieved at its own plant. Now that the customer has signed off on the manufacturing approach, Mr. Leclair plans to revisit the process to see whether Mastercam’s toolpath strategies can further reduce manufacturing cycles.

During the past few years, Costa Precision’s efforts to ensure the requisite precision without sacrificing manufacturing profitability have paid off. In 2008, on-time deliveries were consistently between 95 and 100 percent, even in the face of sometimes overly optimistic customer expectations, and business volume increased by nearly half compared with 2007.

Related Content

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)