Aerospace

Aerospace Top Conference Postponed Due to Coronavirus

The new dates are November 23-24, 2020.

Read MoreDoes Asia's Low-Cost Manufacturing Option Still Make Sense?

As U.S.-based companies try to stay ahead of COVID-19, global supply chains are under renewed scrutiny. Are uncertainties and delays caused by global crises worth the short-term cost savings?

Read MoreComau, Exechon Collaborate on Machining Center Design

The machining center will be designed particularly for manufacturing lightweight framing and structural components for the automotive and aerospace sectors.

Read MoreTaking an Automated Aerospace Approach

A flexible manufacturing system helps an Indiana job shop run a high mix of aerospace work for long stretches of time and function more like a contract shop.

Read MoreMultitasking Forms Hub of Shop’s Propeller Production Efficiency

Outsourcing machining for complex hub assemblies resulted in months-long lead times and lack of control. A Mazak multitasking machine allowed Whirlwind Propellers to bring production in house.

Read MoreDeveloping a Five-Axis Solution for Machining Superalloy Aerospace Parts

Growing involvement in producing multi-blade aerospace parts made of superalloys presented Pietro Rosa with some machining challenges. Starrag’s LX 021 five-axis VMC helped the shop achieve tight tolerances and integrated production.

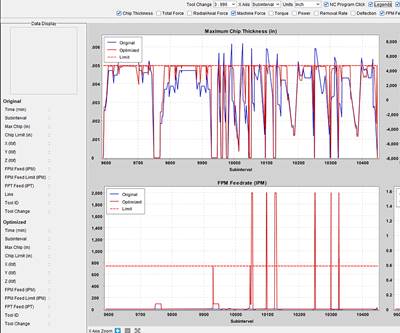

Read MoreAerospace Shop Adopts NC Optimization as a Means of Continuous Improvement

Steelville Manufacturing adopted CGTech’s Vericut NC verification software to safeguard its high-volume/high-mix work, but found unexpected benefits from its Force Optimization module.

Read MoreAerospace Machine Shop Opts for CAM Simulation Over Dry Runs

NCSIMUL Machine software has taken Marton Precision’s G-code program verification from a 16 hour manual process to a mere two hours.

Read MoreLower Buy-to-Fly Ratios with Near-Net Additive Manufacturing

Building up large parts with wire-arc metal 3D printing rather than machining from solid has allowed this aerospace manufacturer to reduce its buy-to-fly ratio dramatically.

Read MoreHow to Become a Defense Industry Machined-Parts Supplier

Defense contractors are looking for capable shops to supply machined workpieces for a variety of major projects. To participate, however, you must have more than just top-notch machine tools and a skilled workforce.

Read More

.JPG;maxWidth=400;quality=70)