Five-Axis

Five-Axis Machining Center Accommodates Small Workpieces

Mitsui Seiki’s compact PJ 303X machining center, to be highlighted at IMTS 2022, provides high precision, speed and versatility for critical parts like lens molds, medical products and EDM electrodes.

Read MoreWhen Automating a Task Beats Automating the Process

A medical manufacturer proves why a high mix of complex work need not deter any manufacturer from automation, whether via robot or pallet system.

Read MoreCompact Machining Center for Small Workpieces

IMTS22: Chiron Group’s Micro5 maximizes precision for small, micro-technical workpieces such as medical, watchmaking, jewelry and small electronics.

Read MoreView From My Shop Episode 5: Inside a Full Five-Axis Shop With KCS Advanced Machining

In this episode of our shop tour series, KCS Advanced Machining takes us inside their shop and breaks down why they decided to invest completely in five-axis machining centers.

WatchView From My Shop Episode 4: Prototype Machining From a Garage Shop

Guy Driscoll’s shop, Metal Parts Machine, is a garage shop that found success with automation. This mom-and-pop shop uses lights-out machining to run parts with 5-axis capabilities, cobots, pallet changers and more.

WatchDigital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read MoreView From My Shop, Episode 3: Expanding a Machine Shop With Budde Precision Machining

Three years ago, Budde Precision Machining was a well-regarded tool shop. Today, new technology has grown its reach and customer base far wider.

WatchFive-Axis Changes Weldments Into Monolithic One-Piece Parts

Moving from welding to five-axis machining enabled Barbco to redesign its weldments as monolithic one-piece parts with improved strength and repeatability.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

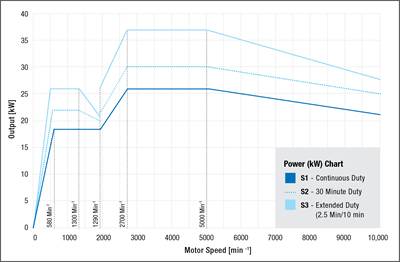

Read MoreBack to the Charts for Productive Milling

Roughing operations can push a CNC spindle to its limits. Understanding how to interpret the horsepower chart can keep these operations within safe limits.

Read More