Compact Machining Center for Small Workpieces

IMTS22: Chiron Group’s Micro5 maximizes precision for small, micro-technical workpieces such as medical, watchmaking, jewelry and small electronics.

Share

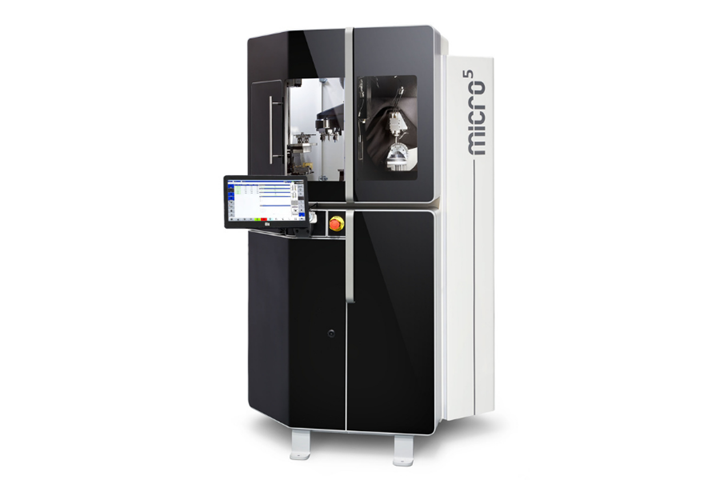

Chiron Group demonstrates its compact Micro5 machining center, which is said to be ideal for machining the smallest medical instruments and delicate parts for the micro-precision industry. According to the company, the machine maximizes precision for small, micro-technical workpieces such as medical, watchmaking, jewelry and small electronics.

With a 5:1 ratio of machine to workpieces, five-times lower weight and a much lower energy consumption than conventional systems, the five-axis Micro5 machining center is said to be extremely compact and quick and easy to set up almost anywhere.

The Micro5 reportedly offers very high static stiffness, repeatability of 0.5 μm and target accuracy of 2 μm. With excellent thermal stability, very high dynamic rigidity and acceleration of 2 g, the compact machine is made for high-speed machining.

The central element of the Micro5 is a high-performance milling spindle that is said to be the size of a refrigerator. This reduces the machining time significantly compared to larger machines. Due to its high rigidity, the compact, five-axis machining center promotes high precision and optimum surface quality. At 500 watts, the Micro5 also consumes very little energy, and it is operated via an intuitive human-machine interface (HMI) panel. It features a noise level under 50 decibels.

Chiron also provides the Feed5 six-axis robot for automated loading and unloading. As compact as the Micro5, the Feed5 is said to be useful for enabling increased autonomy and productivity for longer production runs. The maximum workpiece size for the Micro5 is 50 × 50 × 50 mm.

Related Content

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

.jpg;maxWidth=300;quality=90)