Tech Trends from TIMTOS

This slideshow offers examples of some of the technology spotted at this year's iteration of TIMTOS, Taiwan's biennial machine tool exhibition.

Taiwanese manufacturers continue to advance capabilities. The gallery below depicts examples of a number of trends I spotted at TIMTOS 2013, including:

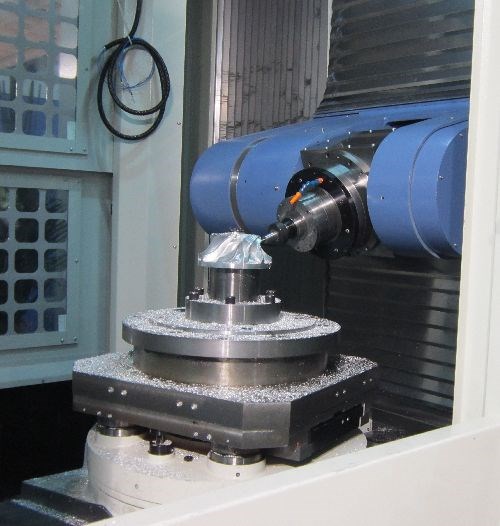

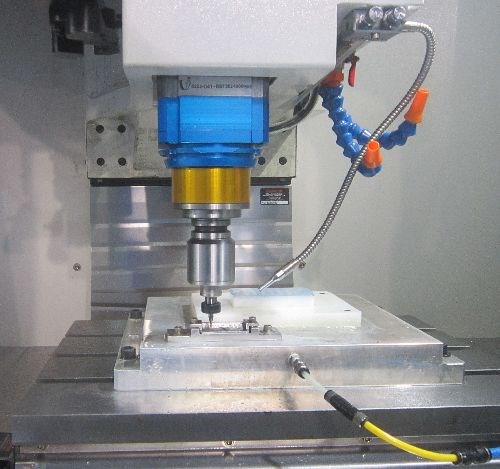

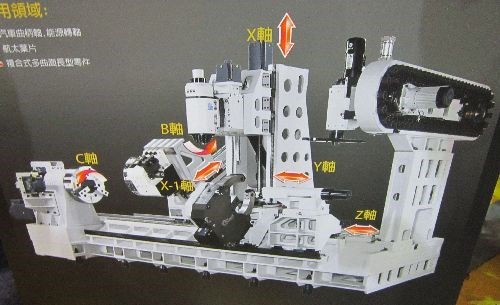

Complex Motion. Rare was the machining center supplier that didn’t offer a model with more than three axes, and most supplied equipment capable of full simultaneous five-axis moves. Increasingly, machine axes aren’t traversing via ballscrew, either—linear motors seemed ubiquitous on the show floor, appearing in equipment ranging from HMCs and VMCs to grinders and EDM equipment.

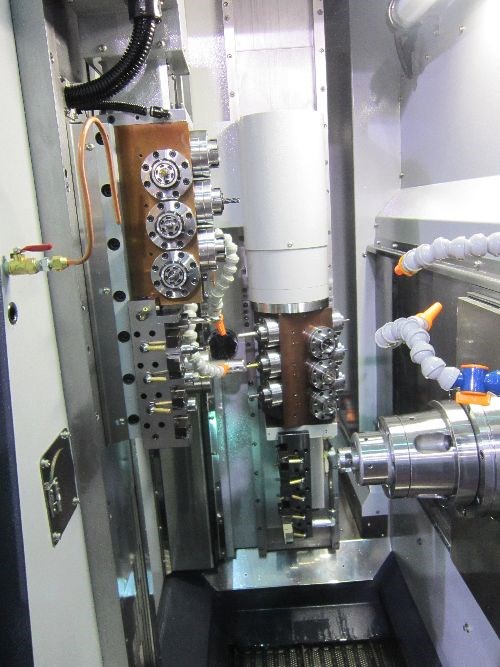

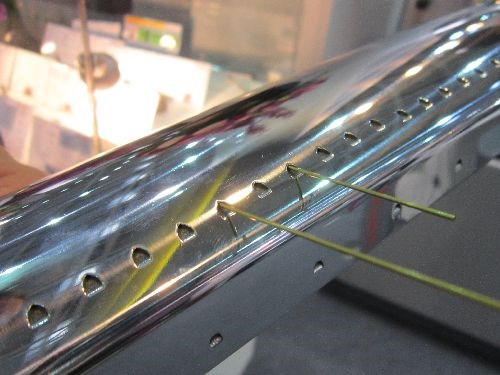

Multiple processes, one platform. Turn-mill machines were also a common sight at the show, and the range of offerings included more than just lathes with live milling and drilling tools. In addition to subspindles for part hand-off, notable offerings included machines with more than two turrets to balance production between the main and subspindle and Y-axes for off-center milling and drilling, among others. This trend extends beyond just turn-mills--one supplier, for instance, showcased a VMC with integrated laser marking.

Advanced control technology. More so than simpler configurations, five-axis and turn-mill machines depend on CNC features such as tool centerpoint control, robust simulation, machine monitoring and so forth. Taiwanese builders like YCM, Chevalier, Chmer and Tongtai, among others, are increasingly developing their own such features rather than sourcing from elsewhere.

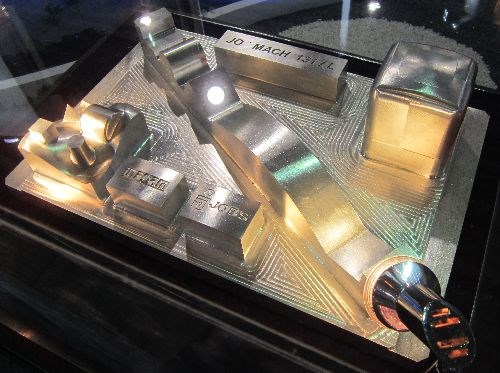

Component suppliers step up. King Wang, chairman of TAMI's machine parts & elements committee, said Taiwan's machine parts and component industry has made considerable progress during the last few years. In fact, total export value for this sector amounted to nearly as much as machine tools themselves. Additionally, TIMTOS 2013 marked the first time that the Machine Tools Industry Awards for Excellence in Research and Innovation included a category specifically for machine components.