Zeiss Measurement Software Features Automated Fault Analysis

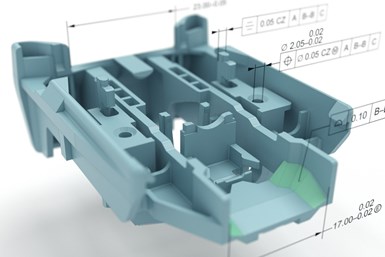

Zeiss Calypso 2023 offers an improved fault analysis, optimized workflows for optical CMMs, better usability and advanced GD&T evaluations.

Share

Zeiss Industrial Quality Solutions has released a new software version of Zeiss Calypso, a general measuring software that enables both tactile and optical measurements with Zeiss CMMs, as well as the verification and analysis of the resulting 3D data.

Zeiss Calypso 2023 offers an improved fault analysis, optimized workflows for optical CMMs, better usability and advanced general dimensioning and tolerancing (GD&T) evaluations according to ISO-GPS and ASME.

Zeiss Calypsos’ improved, automated fault analysis displays faults in an interactive report, and automated plots show every detail. The report enables dynamic zooming, which offers new possibilities for small mechanical parts and a variety of electronic devices.

With this year’s release, Zeiss Calypso offers new evaluation functionalities for CMMs, such as Zeiss O-Detect. The user can, for example, use the overview camera for navigation or automatically search for geometrical elements in the image acquired.

The new toolbox is designed to reduce the number of working steps, and frequently used testing features can be stored as favorites in an individual toolbox. Users can customize Zeiss Calypso specifically to their needs by, for example, adding Calypso freeform or Calypso curve.

“When developing Zeiss Calypso, we wanted to create a software for efficient, secure and fast processing of data volumes in an intelligent way,” says Christoph Grieser, head of global software sales at Zeiss Industrial Quality Solutions. Grieser adds, “We continuously develop and optimize our software. Additionally, new applications permanently generate the need for new functionalities, which we integrate in our software. We have a clear goal: to continue being a reliable partner to our customers.”

Related Content

-

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

How to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.