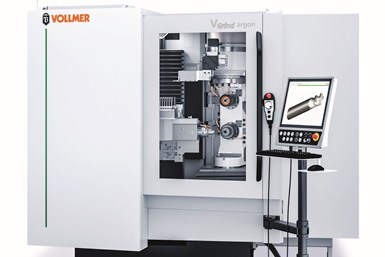

Vollmer Grinding Machine Features Double-Spindle Design

Eastec 2023: VGrinds are said to be suitable for machining rotary tools made from carbide, such as drills, milling cutters or reamers.

Share

Autodesk, Inc.

Featured Content

View More

Vollmer’s new VGrind Argon is one of three new tool grinding machines from the sharpening specialist. It is based on Vollmer's double-spindle concept, which enables precise and efficient multilevel machining. The company showcases the grinding machine in booth 1748 at Eastec 2023.

While other VGrind models can be configured for specific customer requirements, the VGrind Argon is a special edition that Vollmer has designed for fast and cost efficient access to the world of tool grinding. VGrinds are said to be suitable for machining rotary tools made from carbide, such as drills, milling cutters or reamers. With these machines, Vollmer is expanding its range of tool and cutter grinders, which also includes the VGrind 340S and VGrind 360S models.

Vollmer designed the compact VGrind Argon machine as a cost-efficient entry into the world of tool grinding and provided them with functional features as standard. The Argon is equipped with an Internet of Things (IoT) gateway and has an internal wheel measurement system, which measures the grinding wheels and monitors their wear. It also has a four-wheel grinding wheel changer as well as an internal pallet loader and is designed for fully automatic operation.

“Our unique VGrind approach of multilevel machining has established itself as a reliable and highly precise technology in the global market for tool grinding,” says Jürgen Hauger, CEO of the Vollmer Group. “With our new VGrind models, we are specifically responding to different requirements that tool manufacturers and sharpening services around the world have placed on us: On the one hand, there are individual configurations of the machines with regard to flexibility and precision; on the other hand, there is an outstanding price-performance ratio.”

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)