Visi 2020.1 Automates Deburring Programming

The 2020.1 release of Visi mold and die software enhances the progressive die design processes and provides enhancements for the Reverse module.

Share

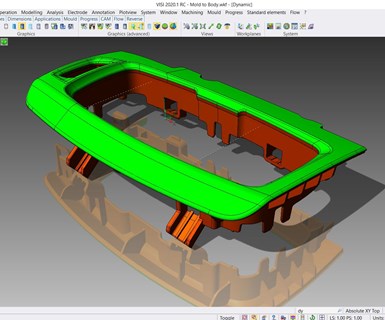

The 2020.1 release of Visi mold and die software, available from Hexagon Manufacturing Intelligence, enhances the progressive die design processes and provides enhancements for the Reverse module. Upgrades to the new part unfolding feature provide the ability to work directly on the original solid model, support blanking functionality and manage parts with non-linear bends. Sheet metal part recognition provides an improved graphical representation of the part, analyzed by identifying bends, planar faces and features.

Visi Product Manager Marco Cafasso says the major advantage of the new technology is the associativity provided with the original model during the die design process. “It allows the original part to be modified, and changes to be automatically propagated on the banked part. This new feature allows all the linked parts to be rebuilt in reference to a modification done to the original part.”

The Reverse module has been enhanced with additional functionalities for both Reverse and Casting processes, including new features to support scanning and surfaces generation. “A new Best Fit feature aligns a stock model to the final solid model by setting tolerances on different faces,” says Mr. Cafasso. “This is useful for the casting market, as it allows the cast model to be scanned, achieving a best fit alignment with the final geometry, producing an optimized tool path with reduced machining time.” The stock model can then also be used for machining simulation purposes.

The Compare feature has been improved to provide an enhanced graphical evaluation of the results, and to display distances between the scanned model and the final solid model. “The enhancements achieved provide quality improvements to both processes as well as time saving from the scanning to the manufacturing process.”

Visi’s deburring strategy creates a tool path to deburr the sharp edges of a workpiece with a spherical tool. The tool is positioned in the bi vector of the automatically detected sharp edges. Automatic tilting and linking is then applied to avoid collisions. “As the whole process is highly automated, this machining strategy significantly reduces deburring setup time,” says Mr. Cafasso.

Related Content

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.