Velo3D Software Enhances Control Over 3D Printing Process

The software’s new features include user-selectable core parameters, preprint analysis to identify potential costly and time-consuming errors, and rapid resequencing for multipart prints.

Share

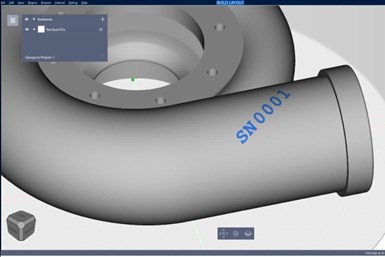

With the new labeling module in Flow 5.0, users can quickly add text to the print file, enabling serialization of parts or other identifying marks. Photo Credit: Velo3D

Velo3D, a metal additive manufacturing (AM) technology company for mission-critical parts, has updated its Flow print preparation software. Flow 5.0 was developed to unlock an array of new capabilities for engineers using Velo3D’s fully integrated solution, including user-selectable core parameter sets that provide enhanced control over builds with the ability to assign different parameters to any part on the build plate. This improvement, in addition to Flow’s ability to apply skin and contour overrides, gives customers enhanced control over the final material properties of printed parts.

Flow 5.0 includes checks and messages that identify possible errors before a build even starts, reducing the likelihood of customers experiencing failures in their builds. In doing so, engineers can be confident that a part will print successfully before the process begins. Flow also includes labeling for objects. Customers can easily add alphanumeric characters, such as serial numbers or other unique identifying text, to their builds within the Flow print preparation software to clearly identify and label instances of their parts. Once the print file is produced, the characters can be updated through a Label Updater tool.

The release also enables a faster method to calculate build times for builds of different part quantity. After a part has been prepared for print, users can vary the quantity of that part and see updated build times to better understand the economics of scaled production. This enables contract manufacturers to speed up their quoting process and accelerate OEM planning and scheduling.

The Flow print preparation software is a key part of Velo3D’s fully integrated metal AM solution. The software takes traditional CAD files and turns them into print files without any specialization or design for additive manufacturing (DfAM). Other parts of the solution include the Sapphire family of printers, Assure quality assurance software and the underlying Intelligent Fusion manufacturing process that provides consistent, repeatable outcomes across different Sapphire printers from the same print file.

Related Content

-

Additive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

-

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

-

The Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

.jpg;maxWidth=300;quality=90)