Universal Workholding Solution Grips Challenging Parts

IMTS22: Norgren Workholding’s Adaptix can be quickly set up and grip unique parts for high mix, low volume orders.

Share

Takumi USA

Featured Content

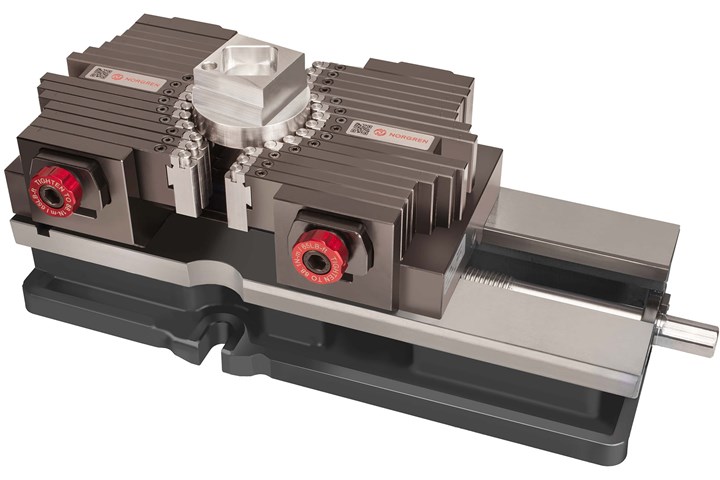

View MoreNorgren Workholding demonstrates Adaptix, its unique universal workholding solution, which the company says can rapidly adjust to powerfully grip challenging workpieces. Adaptix’s innovative technology is said to ensure repeatability and precision are maintained throughout the machining process, resulting in more uptime and faster changeovers. Unique shapes can be quickly set up and held for high mix, low volume orders. Its ease of configuration and interchangeable pin tips mean machine operators can reduce set up and changeover times and associated labor costs.

Visitors to the Norgren Workholding’s booth can see the wide range of supporting system components such as tips and studs, which enable the product to adapt clamping forces and grip dependent on the material, as well as see Adaptix in action. Norgren’s team of application engineers will be on-hand to demonstrate Adaptix and to answer technical questions.

Related Content

-

Siemens Software Boosts Efficiency in Parts Manufacturing

IMTS 2024: Siemens Digital Industries Software unveils its NX X manufacturing software, a cloud-based and data-secure CAD/CAM solution for part manufacturing and efficiency.

-

FANUC Details Robotic Vision, ROBODRILLS and More at IMTS 2024

FANUC’s IMTS 2024 booth includes real-time demonstrations that show the abilities of its equipment, including robots, controllers and machine tools.

-

Chiron Group Unveils Virtual Showroom & Live Demos at IMTS 2024

Chiron Group combines the best of both worlds at IMTS 2024, featuring live demonstrations of their Micro5 and Mill 2000 machines, alongside a cutting-edge virtual showroom. This innovative approach allows visitors to explore Chiron’s full product lineup without the logistical challenges of transporting large equipment.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)