Tungaloy Introduces Barrel-Style Cutting Tool Inserts

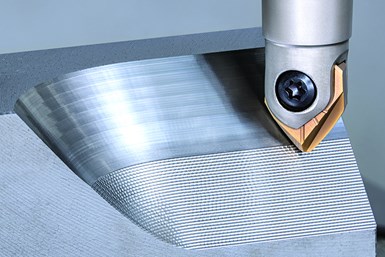

The BallFinishNose indexable barrel-style tool inserts feature an asymmetric shape, which enables users to use the same side of the insert always facing the same direction when set in the tool body.

Share

Tungaloy has expanded its BallFinishNose indexable tool capabilities of profiling complex 3D contours by adding five “barrel-style” inserts for improved cycle time reduction in contoured workpieces.

According to Tungaloy, BallFinishNose is an effective tool in finishing and semi-finishing, particularly on geometric surfaces and complex 3D contours common to die-mold or aerospace applications. The insert features an asymmetric shape, which enables users to use the same side of the insert always facing the same direction when set in the tool body, providing the tool with high repeatable accuracy and reliability, surface quality and predictable tool life.

Tungaloy has added five barrel-style inserts to BallFinishNose to increase its efficiency of 3D profile milling capability. The barrel inserts, named due to the resemblance of the cutting edge shape to a barrel’s profile, consist of cutting edges with larger radii compared with ball nose end mills, creating greater contact between the cutting edge and workpiece. This permits larger step-over increments, maximizing efficiency without compromising on cusp heights and enabling the removal of more material with fewer passes.

The barrel style inserts can be used with existing BallFinishNose cutter bodies. The inserts are designed to fit the cutter bodies in diameters ranging from 12 to 30 mm (from .472" to 1.181"). The barrel style inserts’ cutting edge radii are available in 30, 40, 50, 62.5 and 75 mm, and each set of inserts fit the cutter in diameters 12, 16, 20, 25 and 30 mm, respectively.

Featuring the coolant channels on the insert faces just as those on existing BallFinishNose inserts, the barrel style inserts reportedly ensure optimal coolant delivery close to the cutting area, providing stable and long tool life.

The barrel-style inserts are offered in CH315 insert grade. A combination of extreme wear resistance made possible by the latest physical vapor deposition (PVD) coating technology and fracture-resistant dedicated carbide substrate, the latest CH315 provides the insert with long tool life.

With the new barrel-style inserts in the line, BallFinishNose lends itself to finish machining of 3D complex surfaces and other intricate profiles typical in die-mold and aerospace segments.

Related Content

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.png;maxWidth=300;quality=90)