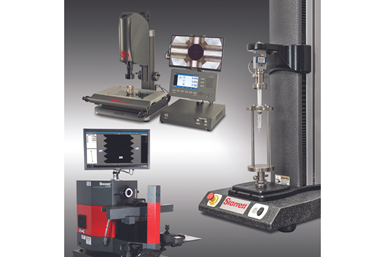

Starrett Measurement Systems Provide Repeatable Results

The company’s optical and video-based measurement systems combine high-resolution images, intuitive software and precision mechanical platforms.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

The L.S. Starrett Co.’s optical and video-based measurement systems combine high-resolution images, intuitive software and precision mechanical platforms to provide accurate, repeatable measurement results.

The new Starrett KMR-MX 200 manual vision system features a manually driven X-Y stage motion paired with a 6.5:1 zoom lens and MetLogix Mx200 digital readout in a stacked display format. Well suited for a range of industries, such as medical, aerospace and defense, that require traceable and secure measurement data, operators can perform measurements without Windows-based software or a PC.

Starrett’s HDV horizontal digital video comparator combines the features of vision and optical comparator technology. Starrett HDV systems feature MetLogix M3 touchscreen software with the M3 DXF/FOV option pack. With this software, the HDV can import DXF/CAD files over a network and make automatic 2D comparisons to an engineering design by using Video Edge Detection, with no need for Mylar overlays as required with conventional optical comparators. This is said to increase measurement throughput while eliminating operator subjectivity.

Starrett’s AVR200 multi-sensor vision system, a full CNC benchtop vision system, is well suited for repetitive measurements and automatic comparison to CAD files. In addition, the Starrett HD400 horizontal dual-lens optical comparator offers a two-lens mount, enabling instant switching between two magnification lenses or video camera adapters.

Related Content

-

Turning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

-

How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

-

Choosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.