Smart Linear Actuator Provides Plug-and-Play Functionality

IMTS22: Ewellix has developed a smart electro-mechanical actuator with extended functionality, for use in demanding applications such as agricultural and construction machinery.

Share

Ewellix showcases the smart actuator CAHB-2xS, which offers four new or enhanced features — in control, accurate position sensors, built-in monitoring/diagnostics and communication. It also reportedly offers a typical MTTF (meantime to failure) of 75 years.

The patented non-contact sensors are said to provide a true absolute position of movement that never require calibration, while motion is constantly monitored with the option to synchronize multiple actuators to offer parallel motion even at full speed. In addition, the CAHB-2xS monitors its own condition and can transmit an error code if it operates outside specifications.

Machine developers can also design new products – or perform upgrades – more easily and quickly using the new actuator, with its plug-and-play functionality. Additionally, the CAN bus command enables users to specify an exact actuator position that is reached at a defined speed and with a maximum force, while the intelligent firmware eliminates the need for calibration or actuator testing.

The actuators have a wide range of potential applications, including agricultural equipment, construction machinery and materials handling equipment. They can also be used in work platforms and scissor lifts, and in electric vehicles such as utility task vehicles (UTV), road-sweepers and buses.

According to the company, the actuator does not require regular overhaul and maintenance, as would be needed in a hydraulic system. Additionally, the new SmartX digital platform associated with the most powerful actuator of the CAHB-2xS series, the CAHB-22S (equipped with a ballscrew), is reportedly capable of delivering a push and pull load of up to 10,000 N.

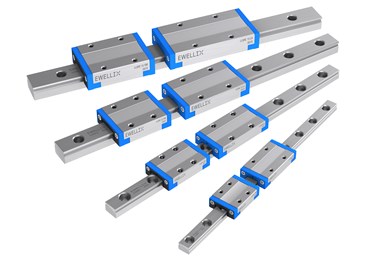

Ewellix is also showcasing its compact, precise LLS miniature profiles rail guides, which are said to deliver long service life, low noise and low maintenance for industrial and laboratory applications.

The LLS series is specifically designed for the industrial and laboratory automation industries featuring low noise operation, smooth motion, high running accuracy and a self-lubricating, low maintenance design.

Common applications can be found in automation pick-and-place, robotic handling, 3D printing or highly demanding medical applications. Specific for the medical industry, these linear guides are RoHS and REACH compliant and are made from stainless steel.

Related Content

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

.jpg;maxWidth=300;quality=90)