Simplified 2D Drawing Software From Num

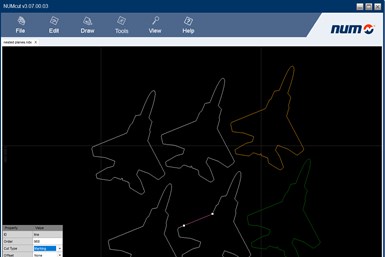

NumCAD’s user interface mimics that of many popular CAD packages and is highly intuitive, making it ideal for people with minimal design experience.

Share

Num has launched a unique 2D drawing tool, NumCAD, that simplifies the design and creation of executable G-code files for CNC cutting machines.

NumCAD runs directly from the machine’s operator panel and also under Windows on any standard PC. According to Num, its user interface mimics that of many popular CAD packages and is highly intuitive, making it ideal for people with minimal design experience.

Simple drawing tools are provided for functions such as line, polyline, arc 2P and arc center-radius; they are backed by a suite of editing tools such as meet two lines, shrink or extend and insert micro-joint, which enables users to customize and modify shapes.

If a user already has a CAD file, NumCAD enables AutoCAD DXF files to be imported. If the user does not have a DXF file, but has created the shape on the CNC cutting machine itself, NumCAD also enables this shape to be imported from their customizable parametric shapes library.

According to Num, the NumCAD software package includes a post processor; shapes or patterns that have been drawn or imported can be automatically converted into an executable G-code file for the CNC cutting machine.

Using NumCAD, each segment of a cut can be set to rapid, marking, rough, medium or fine cut qualities. Both standard shape and custom fly cutting functionalities are available, and associated functions include the ability to control the cut-side placement (kerf compensation) and tilt angle of the machine’s cutting nozzle. Nesting gives the user the option to create complex paths containing the same pattern. With settings like nesting type, number of pieces, sheet size and scaling, Num says the user can create a path that is sized and optimized to their liking. The added alignment settings enable the shapes to be rotated and offset for the minimization and optimization of uncut space.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.