Siemens Updates Software Solutions for Manufacturing

Updates to NX for Manufacturing, Siemens’ software package for part manufacturing, include PrimeTurning, automated deburring and other enhancements.

Share

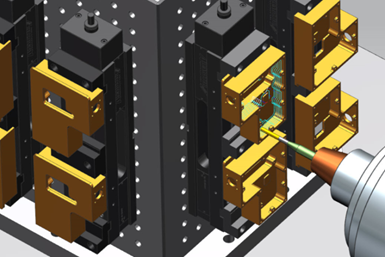

NX CAM In-Process Workpiece

Siemens has released the latest version of NX for Manufacturing, its comprehensive software for part manufacturing that includes NX CAM, NX Additive Manufacturing, NX CMM Inspection Programming, NX Assembly Line Planner and Manufacturing data and process management in Teamcenter.

Notable Updates to NX CAM

The automated Deburring operation has been expanded to automatically recognize part edges with any level of complexity and create multi-axis operations to machine the specified chamfer size.

Users can create different multi-axis operations and use different cutting tool types, including ball, taper or lollipop tools.

The new Rotary Roughing operation is designed to streamline the process of programming cylindrical parts. Advanced toolpath settings, such as controls for tool contact shift and point density, are said to enable creation of smooth, efficient multi-axis roughing operations. Using the rest roughing capability, users can create machining operations for the uncut material from the previous operation. The helical entry ensures gradual engagement with the material, improving the overall machining process.

Five-axis Guiding Curves finishing operations feature includes updates such as tool axis interpolation, multiple cutting path depths and wall stock, designed for creating toolpaths that avoid adjacent walls.

Siemens partnered with Sandvik Coromant to implement PrimeTurning, a cutting methodology that uses CoroTurn Prime to reportedly extend tool life and increase productivity. Users can setup a PrimeTurning for a dual roughing operation (Multi Channel Roughing) and use it in conjunction with continous B Axis.

Smart Machine Kit wizard enables users to create complete machine tool kits, including the definition of machine kinematics models, postprocessors and CSE drivers.

NX CAM’s automated holder creation capability recognizes the features and associated dimensions of the 3D holder solid models provided by cutting tool vendors and automatically populates them.

Multi Setup IPW flow capability enables users to program complex setups by correctly displaying the In-Process Workpiece (IPW) in its current machined state.

Manufacturing Data and Process Management

Several important improvements have been implemented in Teamcenter, streamlining the manufacturing data and process management:

- Use Teamcenter to work with multiple NX versions

- Easily access classified manufacturing resources using the Manufacturing Resource Library (MRL) dashboard in Active Workspace

- Effectively manage a wider selection of classes based on the DIN 4000-190 industry standard with the expanded device classification in MRL

- Transfer work packages to production using Shop Floor Connect and its new, configurable user interface based on HTML 5

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)