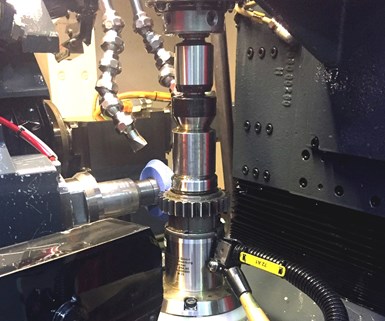

Ringspann's HDDS Mechanical Clamping Mandrel Increases Process Security

Ringspann’s HDDS expanding-sleeve mandrel is designed for clamping spur or taper wheels for gear manufacturing.

Share

Ringspann’s HDDS expanding-sleeve mandrel is designed for clamping spur or taper wheels for gear manufacturing. The HDDS, an inner clamping system, is marketed as a mechanical alternative to hydraulic expanding mandrels commonly used in gearmaking. It provides true running accuracy of equal to or less than 5 microns and achieves absolute expansion some four times larger than many other hydraulic clamping fixtures, the company says.

“Our HDDS can take up workpieces with bores of up to tolerance class IT10,” says Production Manager Joe Thompson. “Most hydraulic clamping fixtures, meanwhile, are only suited to take up workpiece bores up to tolerance class IT7.”

Because mechanical fixtures do not leak, they provide more process safety in series production than hydraulic fixtures, the company says, adding that even the smallest leaks can lead to process interruptions, malfunctions and increased repair outlay. The only source of wear for Ringspann’s HDDS is its clamping disks. Furthermore, the clamping mandrel doesn’t need to be taken from the spindle to replace these disks.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Prioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.