Renishaw Fixture-Modeling Software Streamlines Setup Process

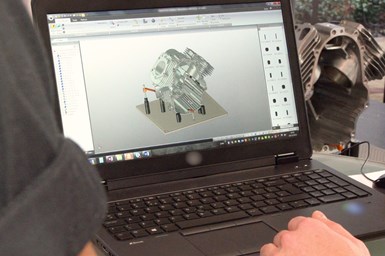

The FixtureBuilder 3D software enables fast creation and documentation of advanced, CAD-based, metrology fixturing setups.

Share

Renishaw’s FixtureBuilder 3D fixture-modeling software enables fast creation and documentation of advanced, CAD-based, metrology fixturing setups for repeatable and productive part inspection. Users have access to the full catalogue of Renishaw metrology fixturing components when designing and documenting their modular fixturing setups.

Renishaw’s FixtureBuilder software features an intuitive interface, complete with component libraries, drag-and-drop functionality and a user-friendly constraint mechanism. Its also features full CAD compatibility and custom libraries, and the software’s “Build It” function automates the generation of work instructions and bill of materials for each fixture setup. This simplifies the purchase of fixturing components and helps users to meet quality standards.

According to the company, FixtureBuilder 8.1 enables the design of fixturing setups in seconds. It exports them to the inspection programming software of choice, using common file formats like IGES, SAT and STEP to ensure seamless functionality and compatibility with industry-standard inspection programs and applications.

FixtureBuilder 8.1 is available via a subscription service, and users receive a complimentary 12-month subscription to the software when they purchase qualifying metrology fixturing products or bundles.

“Our fast and flexible FixtureBuilder software is a powerful addition to any manufacturer’s inspection workflow,” says Will Paul, product marketing manager. “The weakest link in an inspection process is often the ability to design and document comprehensive fixturing set-ups with ease and speed. FixtureBuilder gives our customers confidence in the positioning of their parts.”

Related Content

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.