Red Lion Controls Expands SixTrak RTU Line

Red Lion Controls has added the ST-IPm-8460 to its SixTrak line of industrial RTUs. The company’s Red Lion Workbench software powers the device.

Share

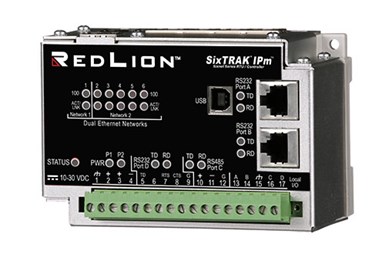

Red Lion Controls expands its SixTrak line of industrial remote terminal units (RTU) with the launch of the ST-IPm-8460, which operates on the Red Lion Workbench platform with an IEC61131-3-compliant editor and runtime engine. Red Lion says it designed the new RTU for applications that need increased processing and communication speed and storage, while maintaining the flexibility and reliability that customers require and expect from Red Lion to monitor and control equipment. The ST-IPm-8460 has achieved UL Class I, Div 2 certification and an ABS listing, while the construction supports operating temperatures from -40°C to 70°C, allowing the RTU to operate in harsh and hazardous locations.

The company says the combination of ST-IPm-8460 and Red Lion Workbench can support large, complex projects across multiple devices. Red Lion Workbench provides customized control, standard language support, debugging and monitoring tools, project automation and controller redundancy. The ST-IPm-8460, for its part, is available for configuration using Red Lion’s EtherTrak-2 I/O modules to scale its functionality to the user’s application.

Red Lion’s ST-IPm-8460 also offers private labeling as well as dual power inputs and support for redundant Ethernet networks to increase uptime, while a multitude of communication ports and supported protocols enable connectivity to a variety of field devices.

Related Content

-

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

-

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

-

Machine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.