Program Provides Support From Design to Physical Part

IMTS22: Bantam Tools provides customers with a process to turn a design into a physical part in order to fit their needs. Through its Turnkey Solutions program, Bantam also provides customers with knowledge of how to make more and the confidence to do so.

Share

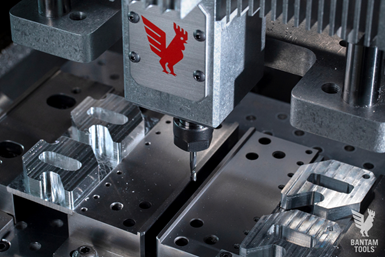

Bantam Tools, the desktop CNC manufacturer, is launching Bantam Tools Turnkey Solutions. This CNC service gives designers, engineers and entrepreneurs the ability to turn designs into physical parts. Bantam Tools engineers will develop a process for machining parts using the Bantam Tools Desktop CNC Milling Machine based on customer needs and then directly provide this knowledge to customers. Afterwards, customers can machine these parts on their own. The goal is to empower Bantam Tools Desktop CNC Milling Machine users to mill with confidence.

The Bantam Tools Turnkey Solutions was set up to help companies make parts faster using the company’s Desktop CNC Milling Machine. The service gives designers, engineers and companies a shortcut when figuring out a process to mill on a CNC machine. Depending on a client’s needs, Bantam Tools will deliver items including work instructions for how to set up and run a job, a .BTP file that saves a job setup in the Bantam Tools software, a Fusion 360 file with vetted CAD model and CAM toolpaths, G-code files exported from a Fusion 360 file, expertly engineered custom fixturing (either designs or fabricated), finished part(s) and a list of suggested machine tooling and accessories for milling the part.

The company says its Turnkey Solutions program evolved from its customers wanting to perfect their designs. Bantam says that when it helped its customers get set up, those customers found greater success and were able to prototype and iterate on-site quickly and easily.

Related Content

-

Tsugami Lathe, Vertical Machining Center Boost Machining Efficiency

IMTS 2024: Tsugami America showcases a multifunction sliding headstock lathe with a B-axis tool spindle, as well as a universal vertical machining center for rapid facing, drilling and tapping.

-

AI, Data and the Digital Manufacturing Future

AI has the potential to reshape manufacturing software — but first, it will require data.

-

Keyence Multi-Sensor Measuring System Targets Quality Control in Metrology

IMTS 2024: Keyence introduces the LM-X Series Multisensor measurement system for high-performance measurement, automated inspection processes, accuracy and quality control.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)