PRAB's Auto-Take Up Cuts Conveyor Belt Adjustment Downtime

PRAB’s new conveyor enhancement automatically tightens belts and eliminates the need for manual adjustments, cutting downtime and preventing belt failure.

Share

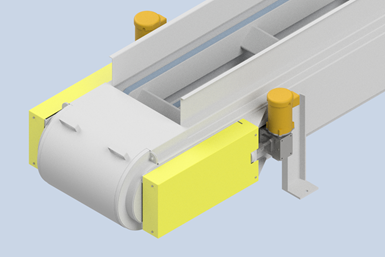

PRAB Inc., has introduced the Auto-Take Up system, a conveyor enhancement designed to automatically tighten belts and eliminate the need for manual adjustments.

PRAB designed the Auto-Take Up to monitor tension using load cells on chain conveyors, including steel belt conveyors, drag conveyors, the PRAB ScrapVeyor and others. The Auto-Take Up system is wired to a programmable logic controller (PLC) panel, which monitors tension and automatically tightens the belt to eliminate manual adjustments and downtime. PRAB says the panel can be added to new conveyors or retrofitted onto existing models. If retrofitted onto an existing conveyor, the system can also be operated using that conveyor’s original control panel. Automatic adjustments can be scheduled during low production times or shift changes.

Related Content

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.