Paperless Parts Quoting Platform Streamlines Estimating Process

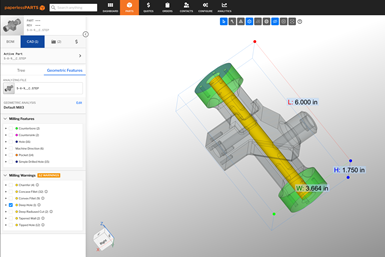

Eastec 2023: Recent updates to Paperless Parts include performance enhancements to the 3D Part Viewer that improve the ability to navigate complex parts and assemblies.

Share

Paperless Parts, an estimating and quoting platform for job shops and contract manufacturers, offers a comprehensive software platform that enables users to quote faster and more accurately, reduce errors in the estimating process and provides shop owners the data and analytics needed to grow their business. Paperless Parts showcases its platform at Eastec 2023 in booth 5567.

Capabilities of Paperless Parts include: a centralized platform for viewing, prioritizing, assigning and managing RFQs; a BOM Builder for quoting that automatically extracts tree structures from CAD files, enabling for easy editing to organize assemblies, and identifying and costing subcomponents and purchased hardware quickly and accurately; a proprietary 3D-geometry engine that can analyze part models and flag potential manufacturability issues customized to a shop’s specific capabilities; and an in-platform PDF viewer that enables users to easily review drawings, make annotations, search for keywords, redact information and compare revisions when quoting from prints.

Recent updates to Paperless Parts include performance enhancements to the 3D Part Viewer that improve the ability to navigate complex parts and assemblies. This is said to improve the user experience when quoting large part files in Paperless Parts, and helps estimators ensure that geometric details don’t go missed when viewing large models.

Related Content

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Manufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.