Open Mind's Updated CAD/CAM Suite Enhances NC Programming

Eastec 2023: HyperMill 2023 includes a new General Transformation Pattern feature that uses a selected reference geometry and searches for the same reference in all other models regardless of its spatial orientation.

Share

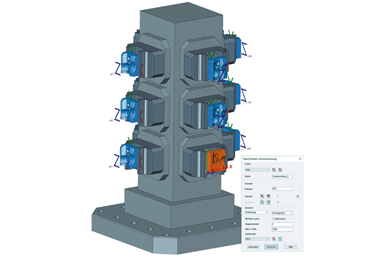

The new General Transformation Pattern feature in HyperMill 2023 makes it easy to program recurring shapes with a single click. Photo Credit: Open Mind Technologies USA Inc.

The new General Transformation Pattern feature in HyperMill 2023 makes it easy to program recurring shapes with a single click. Photo Credit: Open Mind Technologies USA Inc.Open Mind Technologies showcases its latest HyperMill 2023 CAD/CAM software suite, which offers users new and enhanced features for more powerful, simplified NC programming in applications ranging from 2.5D machining to five-axis milling. HyperMill 2023 will be demonstrated at Eastec 2023 in booth 5228. Attendees will also see the integrated HyperMill Maxx Machining finishing module, which is the CAM programming source enabling the use of conical barrel cutter technology to reduce cycle times over 90%.

For easy programming of recurring shapes with a single click, HyperMill 2023 has a new General Transformation Pattern feature. The new feature uses a selected reference geometry and searches for the same reference in all other models regardless of its spatial orientation, creating a general transformation pattern including associated frames.

To provide safe, reliable programming when back boring, a new 2.5D Back Boring machining strategy enables back boring tasks to be programmed on machines with different kinematics conveniently and easily. Toolholders and inserts, as well as monobloc tools, are displayed one-to-one in the virtual machine and checked for collisions. Open Mind says programming the controller for countersinking, deburring and milling tools on the once inaccessible back side of a hole can be done with ease.

An enhanced milling surface extension is offered in HyperMill 2023 for 3D Z-Level Shape Finishing and 3D Profile Finishing strategies. Users can reliably and easily protect sharp edges and divide up machining areas, especially useful for creating high-quality surfaces in tool and moldmaking when combined with a Smooth Overlap feature.

New for HyperMill’s Mill-Turn capability, the Smooth Overlap feature is available for optimizing finishing paths in turning. This function enables flawless transitions when multiple tools or orientations are required for machining, and approach/retract macros can be used normally.

For more flexible, simplified programming of free-form tools, groove plunging with free tool geometry has been enhanced, as all tool geometries can now be used for any type of workpiece contour when roughing, according to the comany. These same tool setting options, approach and retract macros are also available for standard tools.

With the introduction of HyperMill 2023, the NC Optimizer feature in the HyperMill Virtual Machining strategy now optimizes fixed rotary and parallel axes by automatically locating a kinematically correct and collision-free solution. This saves time by eliminating the need to manually interact with the axes.

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.jpg;maxWidth=300;quality=90)