Open Mind Updates HyperMill CAD/CAM to 2021.1

Open Mind’s 2021.1 HyperMill update includes features that give programmers unprecedented control and flexibility, like editing toolpaths after generation.

Share

Open Mind Technologies AG has updated its HyperMill CAD/CAM software suite to version 2021.1, introducing new and enhanced features for 3D, five-axis and mill/turn machining. Key innovations include a new Interactive Edit Toolpath capability that enables toolpath editing after initial generation. The company says the ability for programmers to adapt toolpaths by trimming and removing sequences for component conditions should be useful for optimizing tool and mold making.

HyperMill 2021.1 now offers an import function that retrieves face quality information and metadata when importing CAD data from neutral or native formats and attaches data to the imported faces in HyperCAD-S, making the information available to HyperMill and its machining processes.

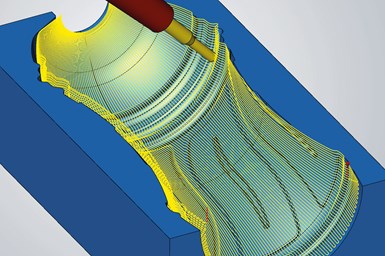

A new five-axis radial machining strategy allows programming bottle shapes and similar cavities in HyperMill, resulting in high-quality surface finishes. Joining this strategy is a new radial projection method that calculates toolpaths and applies the most productive possible machining strategies. During five-axis machining, HyperMill can also apply its High-Precision Surface Mode and Smooth Overlap strategies to ensure optimal surface quality and clean transitions.

HyperMill 2021.1 also offers several enhanced multi-blade strategies. The new strategies allow the use of any number of surfaces for the suction and pressure sides, simplifying the process of extending blade surfaces, and the flank-milling strategies result in smaller deviations on the suction and pressure side.

The software update also supports fillets with a variable radius and integrates a new, powerful Simulation Center for generic NC data in turning and milling operations. The Center enables faster simulation, independent collision checking and extensive analysis functions.

Additional new features in HyperMill 2021.1 include an XY Optimization command for 3D profile finishing, an Align Best Fit command to match components with like-geometry and integration between the Mill-Turn Module’s high-performance mode and three-axis simultaneous roughing strategy.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

.jpg;maxWidth=300;quality=90)